One Stop Service Turnkey PCB Electronics Custom Pcb Assembly Process

-

Highlight

Custom Turnkey PCB Electronics

,One Stop Service Turnkey PCB Electronics

,Custom Prototype PCB Assembly

-

Product NameTurnkey PCB Assembly

-

PCB Assembly ProcessNew Energy PCBA Assembly

-

PCB FinishHASL, Electrolytic Gold, Electroless Gold, Electroless Silver, Immersion Gold, Immersion Gold, Immersion Tin, And OSP.

-

ApplicationPrototype: 15 Work Days. Mass Order: 20~25 Work Days

-

Surface TreatmentENIG,OSP,HASL,Imm Tin,Imm Silver...

-

InspectionX-ray Analysis, AOI, And Microscope To 20X

-

Copper Thickness0.5oz-6oz

-

Base MaterialFR4/CEM-1/Aluminum/CEM-3

-

Place of OriginCHINA

-

Brand NameXHT

-

CertificationISO、IATF16949、RoSH

-

Model NumberXHT Turnkey PCB Assembly-3

-

Minimum Order QuantityLow MOQ

-

Packaging DetailsCarton with foam bag

-

Delivery Time5-8 work days

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability600000+ PCS/mouth

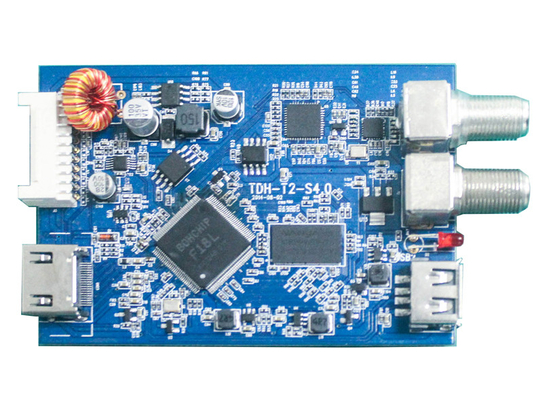

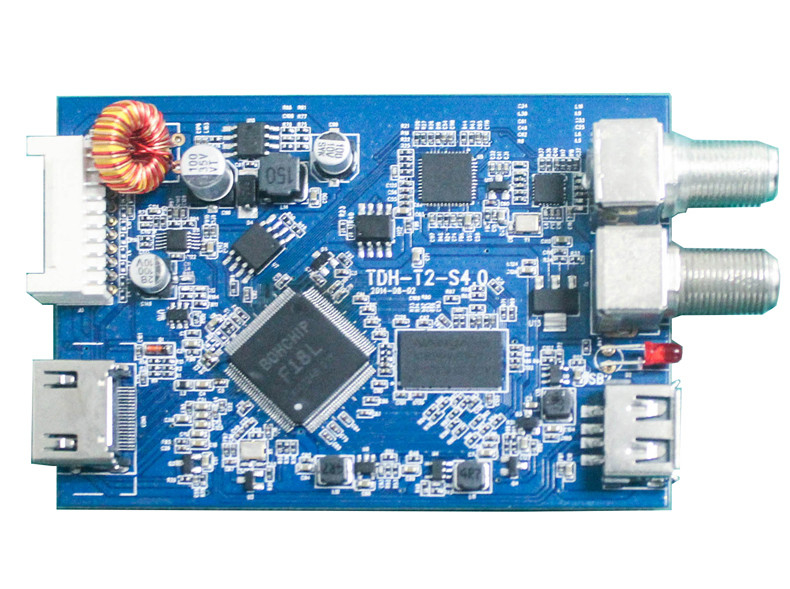

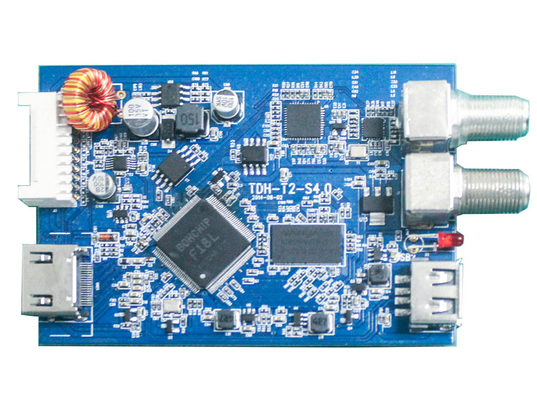

One Stop Service Turnkey PCB Electronics Custom Pcb Assembly Process

Custom One Stop Service Turnkey PCB Assembly For Electronics

Turnkey PCB Assembly

We offer complete, partial, commissioned and packaged turnkey PCB assembly services for prototype to medium production batches. Some operations require complex tasks to be completed in a specific time, splitting all components into specific custom PCB locations. PCB turnkey assembly is a faster form where you need to focus on PCB design and the manufacturer can manage everything.

The industry must manage reliable production assembly in order to provide smooth operations for your organization, which will help improve time efficiency. Turnkey PCB assembly gives you immediate action in your organization, which will enable you to handle all aspects of PCB operation in your organization.

According to the plan, the quantity, type, BOM and Gerber document specifications of the production level are subjected to many demanding deliberations. We carefully examine and analyze all aspects of your turnkey PCB assembly requirements to ensure that no criteria are overlooked. Our flexible use of human resources and moderately technical PCB equipment proves the reliability of our delivery.

Turnkey PCB Assembly Capabilities

| Item | Capability |

| Parts procurement | Full Turnkey, Partial Turnkey, and Kitted |

| Assembly Types | Surface Mount (SMT), Through-hole, Mixed Technology, Single and double-sided SMT/PTH. |

| Solder Type | X-ray analysis, AOI |

| PCB process | Lead-free tin spray |

| PCB layers | Single layers |

| Material | High TG FR4 |

| Lead time | Prototype: 15 work days. Mass order: 20~25 work days |

| PCB Finish | HASL, Electrolytic gold, Electroless gold, Electroless silver, Immersion gold, Immersion gold, Immersion tin, and OSP. |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

| Turnkey pcb assembly certification | IATF16949 /ROHS/ISO9001 |

| Application areas | Auto,Industrial,Medical,Comsumer,LED |

| Design file format | Gerber RS-27, 274D, Eagle and Auto CAD's DXF, DWG BOM, and Pick and place a file |

What is Turnkey PCB Assembly?

Providing turnkey PCB assembly services means that the supplier will handle all tasks including parts procurement, manufacturing, assembly and final delivery!

What are the benefit of full turnkey PCB assembly service?

Full turnkey PCB assembly service offers several advantages, including ease of management, small or large batch assembly, multiple services, cost savings, fast delivery times, and more!

What are the factors that determine the cost of turnkey printed circuit board assemblyservice?

Board Quantity

Type of printed circuit boards

Number of SMT Pads

Number of Through Hole

Number of BGA components and Parts

Complexity of printed circuit board assembly & more.

How can I get a quick quote for turnkey PCB assembly?

1. Gerber file of the bare PCB board

2. BOM (bill of material) for assembly

3. To short the lead time, please kindly advise us if there is any acceptable components substitution

4. Testing guide and test fixtures if necessary

5. Programming files and programming tool if necessary

6. Schematic if necessary