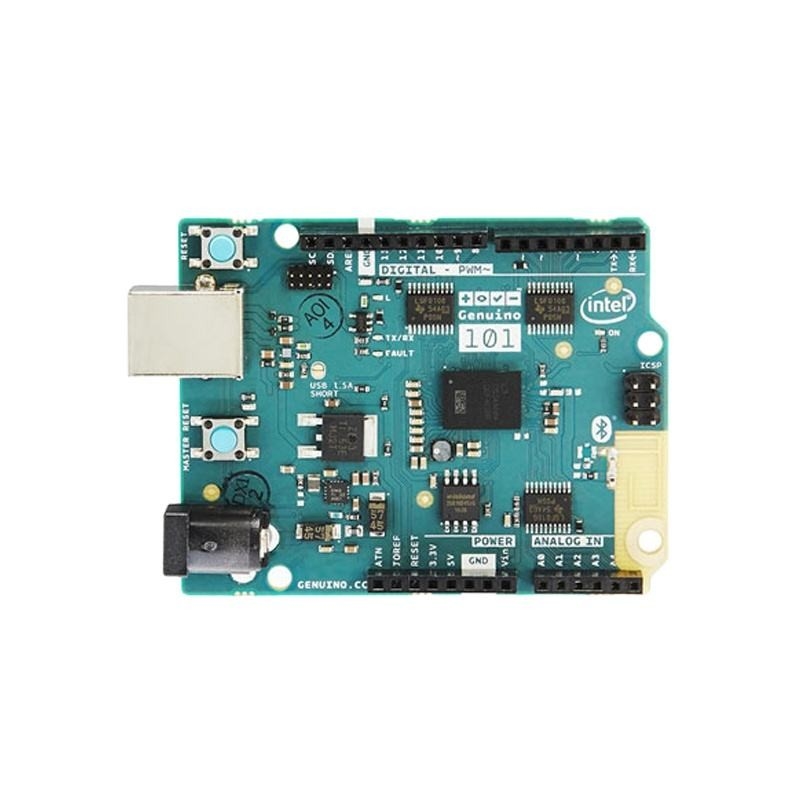

Industrial Control Multilayer Low Volume PCB Assembly Services with Customized Design

-

Highlight

Industrial Control PCB Assembly Services

,Low Volume PCB Assembly Services

,Low Volume PCB Assembly

-

Base MaterialFR4, Aluminium, TG, Rogers, CEM-1

-

Board Thickness1.6mm, 0.5~3.2mm, 0.2-3.0mm, 0.3~2.5mm, 2.0mm

-

ServiceOne-stop Service, PCB&PCBA, ODM And OEM

-

TypeCustomizable, Electronic Board, Electronic PCB Assembly, Alarm Pcb Board

-

Copper Thickness1oz,0.5-2.0 Oz,1-3oz,0.5-5oz,0.5-4oz

-

Surface FinishingHASL, OSP, ENIG, HASL Lead Free, Immersion Gold

-

Min. Line Width3mi, 4mil, 0.1mm, 0.1mm(Flash Gold)/0.15mm(HASL), 0.1 0mm

-

Min. Hole Size0.25mm, 0.1mm, 0.2 Mm, 0.15-0.2mm, 0.1mm-1mm

-

Place of OriginCHINA

-

Brand NameXHT

-

CertificationISO、IATF16949、RoSH

-

Model NumberXHT Volume PCB Assembly-7

-

Minimum Order QuantityNO MOQ

-

Packaging DetailsCarton with foam bag

-

Delivery Time5-8 work days

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability600000+ PCS/mouth

Industrial Control Multilayer Low Volume PCB Assembly Services with Customized Design

Advantages of multilayer circuit boards

1, the multi-layer circuit board assembly density is high, the size is small, with the volume of electronic products is getting smaller and smaller, the function of PCB circuit board is also put forward higher requirements, the demand for multi-layer circuit board is also increasing.

2, the selection of multi-layer PCB circuit board laying line is convenient, the length of the laying line is greatly shortened, the laying line between the electronic components is reduced, but also improve the data signal transmission rate.

3. For the high-frequency circuit, after entering the ground, the signal line has a stable and low characteristic impedance to the ground, and the characteristic impedance of the power circuit is greatly reduced, which has a significant intercepting effect.

4. For electronic products with higher requirements for heat dissipation function, metal core heat dissipation layer can be set up on multi-layer circuit board, which is convenient to satisfy the requirements of shielding, heat dissipation and other special functions.

Why choose us

1, the multi-layer circuit board assembly density is high, the size is small, with the volume of electronic products is getting smaller and smaller, the function of PCB circuit board is also put forward higher requirements, the demand for multi-layer circuit board is also increasing.

2, the selection of multi-layer PCB circuit board laying line is convenient, the length of the laying line is greatly shortened, the laying line between the electronic components is reduced, but also improve the data signal transmission rate.

| Material | CEM-1, CEM-3, FR-4, Aluminum, Rogers, high Tg etc. | |||||

| Board thickness | Mass production: 394mil(10mm) Samples: 17.5mm | |||||

| Surface finish | HASL, OSP, Immersion Gold/Silver/Tin, ENIG, Gold Finger | |||||

| PCB Max panel size | 1150mm × 560mm | |||||

| Layer | 1-64 L | |||||

| Min hole size | Mechanical drill: 6mil(0.15mm) Laser drill: 3mil(0.075mm) | |||||

| PCBA QC | X-ray, AOI Test, Functional Test,QC, QA, QE | |||||

| Special Process | Buried Hole, Blind Hole, Embedded Resistance, Embedded Capacity, Partial-hybrid, Partial high density, Back drilling, impedance requirement, and Resistance control. | |||||

| Our service | PCB manufacturing, Procurement of Components, SMT/DIP PCBA assembly, Line and functional test, Installation, OEM service | |||||

| Sanforized | Buried via, Blind via, Mixed Pressure, Embedded Resistance, Embedded Capacitance, Local Mixed Pressure, Local High Density, Back drill, impedance control. | |||||

| SMT Capacity | 700Million Points/Day, BGA 01005 | |||||

| DIP Capacity | 0.5Million Points/Day | |||||

| Certificate | RoHS/ISO9001/TS16949/UL/ISO14001/ISO13485 | |||||

Our Advantages

1. Program and functional test and package by Free.

2. High quality: IPC-A-610E standard, E-test, X-ray, AOI test, QC, 100% functional test.

3. Professional service: PCB/FPC/Aluminium Making, SMT, DIP, Component Sourcing, OEM with 21 years experience.

4. Certifications: UL, 94v-0, CE, SGS, FCC, RoHS, ISO9001, ISO14001,IATF16949

Q: What files do you use in PCBA fabrication?

A: Gerber or Eagle, BOM listing, PNP and Components Position.

Q: Is it possible you could offer sample?

A: Yes, we can custom samples for your testing before mass production.

Q: How much time could I get the quotation after sent Gerber, BOM and test procedure?

A: Within 6 hours for PCB quotation and around 24 hours for PCBA quotation.

Q: How can I know the process of my PCBA production?

A: 7-10 days for PCB production and components purchasing, and 10 days for PCB assembly and Testing.

Q. Are my design secure when I send them to you?

Your files are held in complete safety and security while Kerongda is in possession of them.Your files are never shared with any third parties,only our colleagues have access to your design files.Since they are your property,we respect the copyright of your files.The customer controls the disposition of these files per your requirements and written approval.

Q.What is the warranty?

The warranty is 2years.