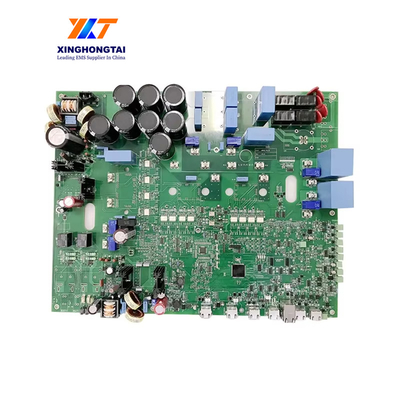

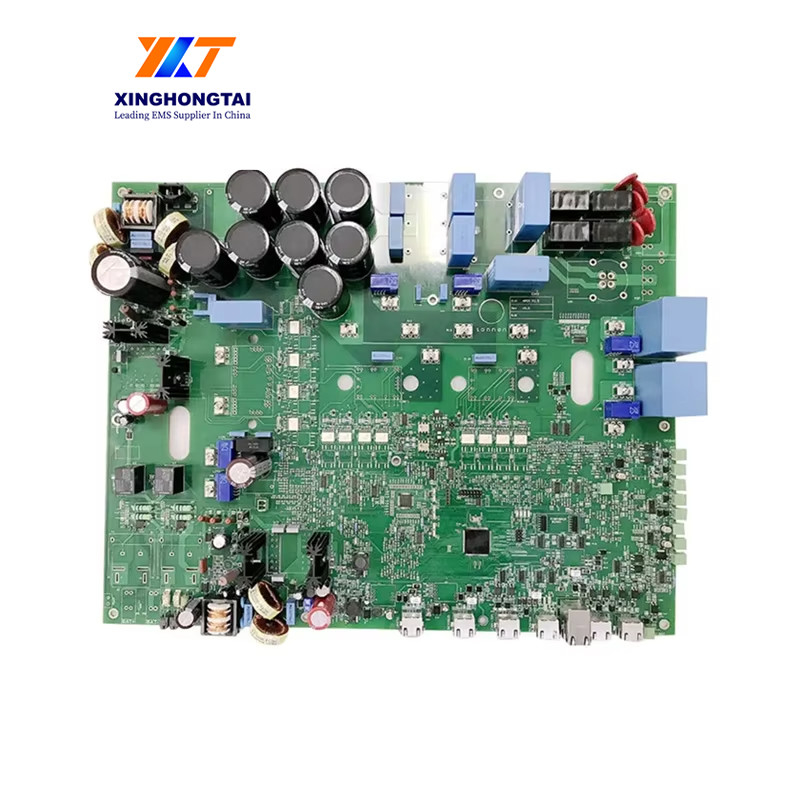

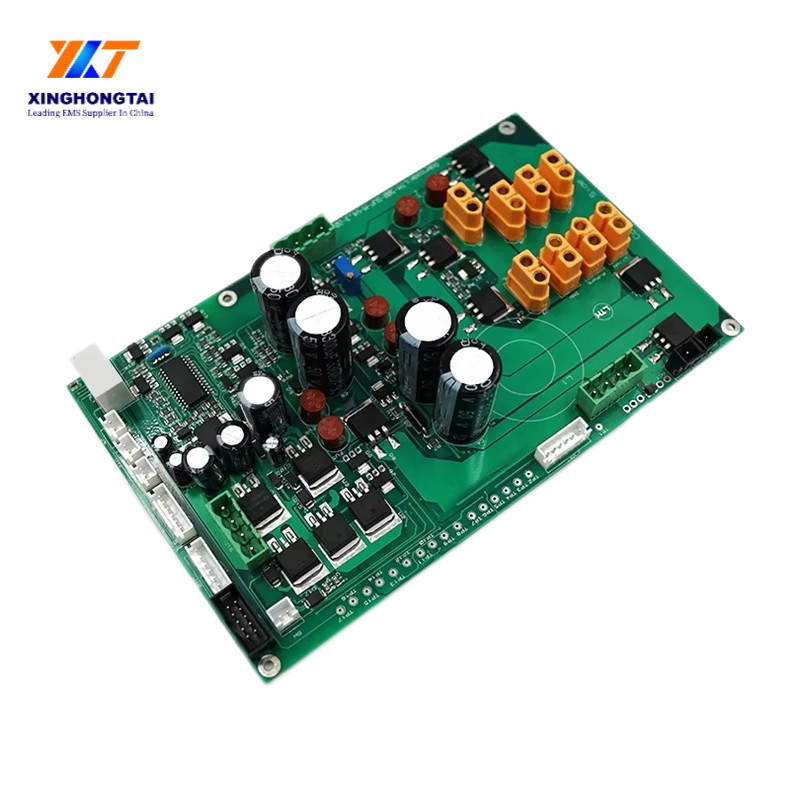

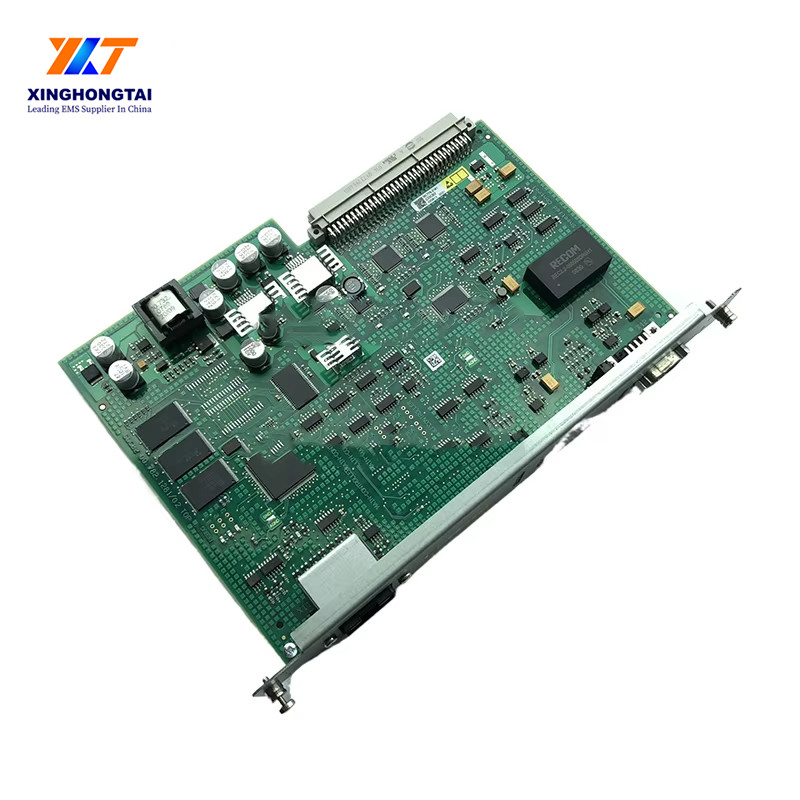

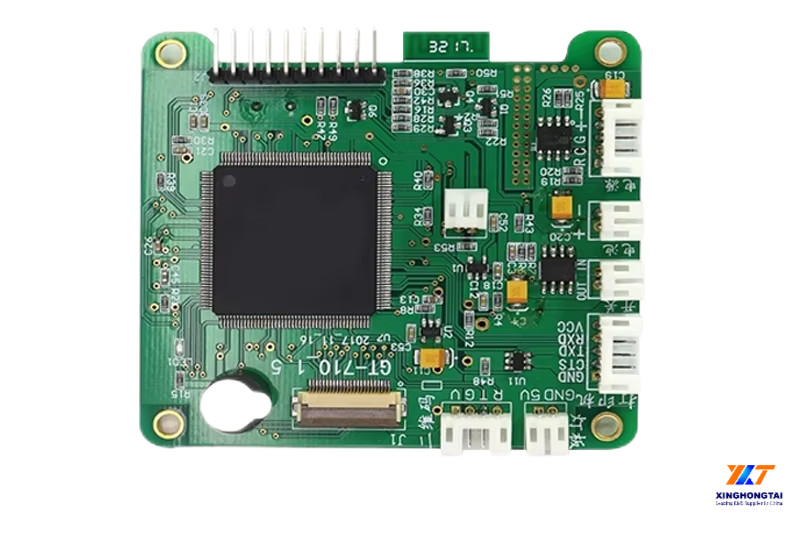

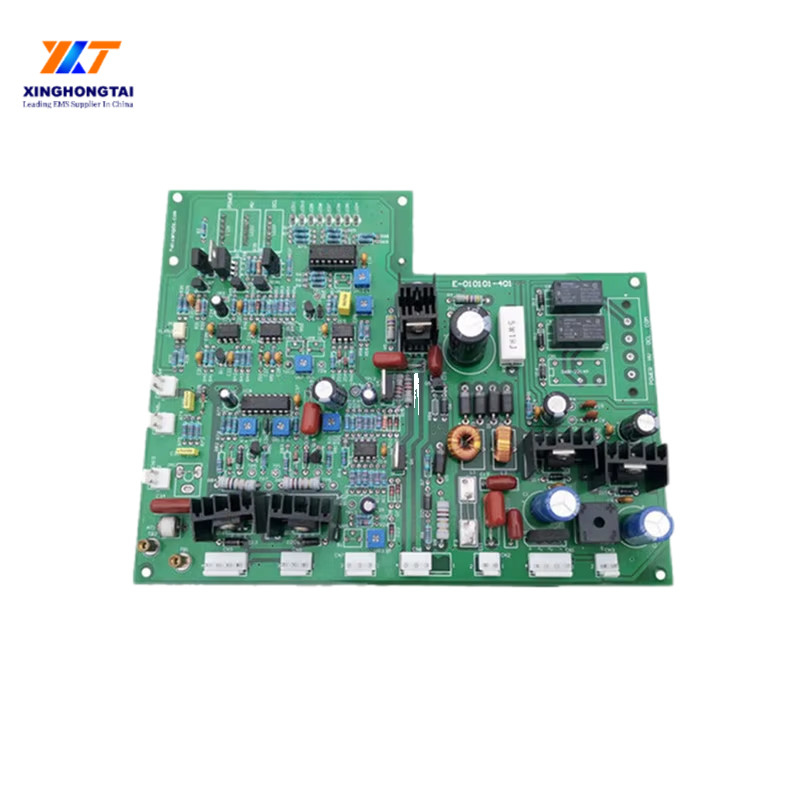

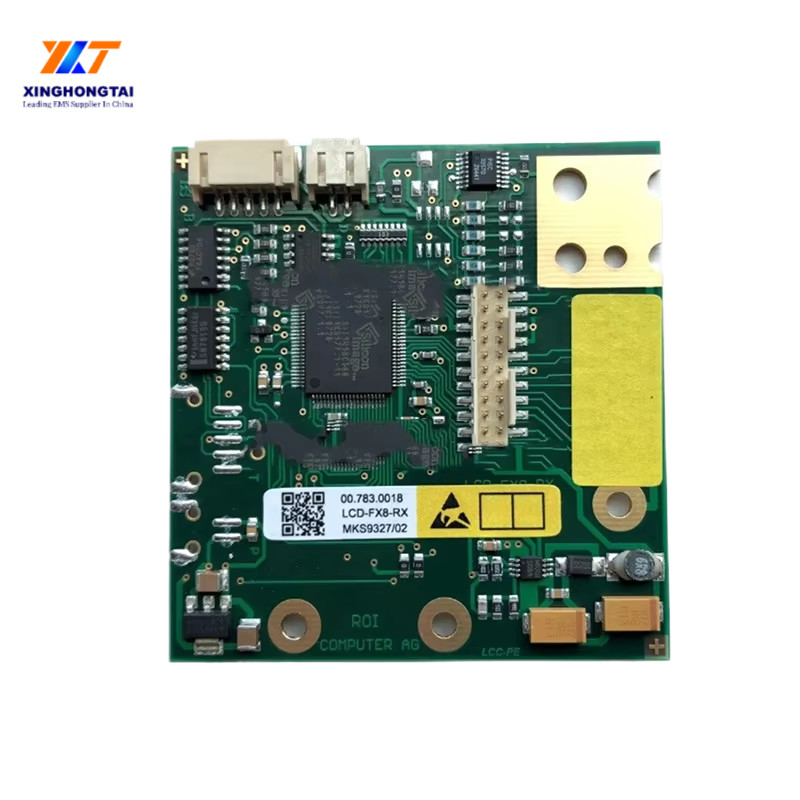

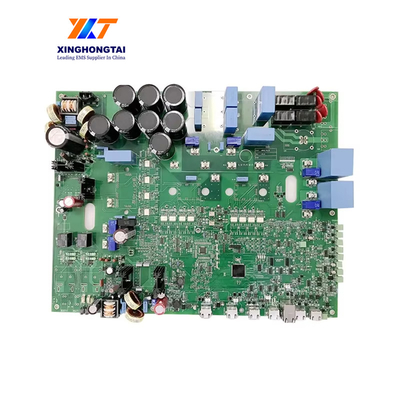

Unique Open-Structure Metal Core PCB Manufacturing Cleaning Robot Circuit Board Assembly

-

Highlight

Metal Core PCB Manufacturing

,Cleaning Robot Circuit Board Assembly

-

Min.Line Width/SpaceMin.Line Width/Space

-

Min. Through Hole Diameter0.15 Mm

-

MaterialMetal

-

Surface FinishingHASL\OSP\immersion Gold

-

Testing Service100% AOI ICT LCT FCT Testing

-

Copper Thickness1-6oz

-

Max. Panel Size600x600mm

-

Min. Hole Size0.2mm

-

Layer Count1-64 Layers

-

Min. Silkscreen Line Width0.1mm

-

Surface FinishHASL, ENIG, OSP, Immersion Silver, Immersion Tin

-

Thermal Conductivity1.0-8.0 W/mK

-

Min. Panel Size50x50mm

-

Operating Temperature-40°C To 150°C

-

Min. Solder Mask Dam0.1mm

-

Dielectric Constant2.5-4.5

-

Board Thickness0.4-3.2mm

-

Solder Mask ColorGreen, Red, Blue, Black, White

-

Place of OriginChina

-

Brand NameXHT

-

CertificationCE,RoHs,UL,FCC,ISO

-

Model NumberXHTBMS07

-

Minimum Order Quantity0

-

PriceUSD1-100/PCS

-

Packaging Detailsgreen energy brown packing, Eco friendly packing

-

Delivery Time5-8 work days

-

Payment TermsL/C, T/T

-

Supply Ability5000

Unique Open-Structure Metal Core PCB Manufacturing Cleaning Robot Circuit Board Assembly

Since our founding in 2004, XHT has been dedicated to being an integral extension of our customers' manufacturing processes, meeting their electronic manufacturing needs with excellence. We are a privately held corporation based in California, with locations in Brisbane and Richardson. Our extensive experience and commitment to quality, on-time performance, and cost-effective solutions for complex products make us the strategic choice for the EMS requirements of leading companies.

We cater to a diverse range of industries, including communications, industrial, instrumentation, medical devices, military, aerospace, transportation, and professional audio.

At our two manufacturing facilities, we offer:

- Over 137,000 square feet of manufacturing space

- High Mix/Low-Medium Volume Manufacturing

- Turn-Key Manufacturing, Testing, Packaging, and Fulfillment

- Thru-Hole PCBA

- Cable Assembly

- Box Build and Rack Assembly

- Prototypes & NPI

- SMT PCBA

- Flex Circuit Assembly

- Mechanical Assembly

Why choose XHT for your Electronic Manufacturing Services (EMS)?

- Personalized, collaborative long-term relationships

- Cost-effective solutions for complex products

- Highly responsive and flexible to your needs

- Strategically focused on your success

- The capability to manufacture PCBA’s, cables, and box/module assemblies ensures the lowest cost solutions

Printed Circuit Board (PCBA) Assembly Highlights

| Category | Details |

| General Capabilities | Surface Mount Technology (SMT), Pin Thru-Hole (PTH), Ball Grid Array (BGA), Functional, Flying Probe, Boundary Scan and In-Circuit Testing, Burn-In, Conformal Coating, RTV Encapsulation, Flexible Circuit. |

| Equipment | Automated Screen Printing, AOI – Automated Optical Inspection, Convection Reflow Oven, General Products Lead Forming, Juki Pick and Place Equipment, Wave Soldering (RoHS and Lead), In-Line and Batch Washers, Ionic Contamination Tester, 2D X-Ray, RoHS XRF Analyzer, Metcal Solder Stations, Agilent 3070 ICT, Acculogic Flying Probe, Thermotron Environmental Chamber, Desiccant Chambers, Dispatch Ovens, Automated Board Handlers, De-Paneling Equipment. |

| Printed Circuit Board Assembly | Ball Grid Array (BGA), Clean and No Clean Flux Systems, Rigid, Flexible, and Rigid/Flexible, Single & Double-Sided, Placement down to 01005, Package Sizes include FBGA, LGA, QFN, Metal Core Insulated, Mixed Technology (SMT and Thru-Hole), RoHS and Leaded Process. |

| Assembly Methods | Automated Assembly, Hand Insertion, Hand Soldering, Reflow, Wave Solder. |

| Additional Services | Conformal Coating, Repair & Refurbishment. |

| Dimensions | Length: Min 2”, Max 18"; Width: Min 2”, Max 18"; Thickness: Min .031”, Max .125". |

| Lead Time (Manufacturing) | Standard 2 weeks. |

| Production Volume | Low Volume to High Volume, Prototype. |

| Industry Focus | Communications, Industrial, Instrumentation, Medical Devices, Military/Aerospace, Transportation, Professional Audio. |

| Industry Standards | AS9100D/ISO-9001:2015 Certification, NIST Standards, MIL-STD-45662, IPC 610 Class II & III standards, RoHS compliant, ITAR Registered, FDB Device License, NCSDC Certification. |

| File Formats | AutoCAD (DWG), DXF, Microsoft Excel, GIF, JPEG, PDF, TIFF, SolidWorks, Gerber, ODB++, CADASCII. |

Packing and Shipping:

Product Packaging:

The EMS PCB Assembly product will be packaged securely in anti-static bags and placed in a sturdy cardboard box with protective foam inserts.

Shipping:

We offer worldwide shipping for the EMS PCB Assembly product. Shipping options include standard, expedited, and express delivery. Customers can choose their preferred shipping method during the checkout process.

All shipments will be tracked and customers will receive a tracking number once the product has been shipped. Shipping fees will be calculated at checkout based on the destination and selected shipping method.

![]()

FAQ:

Q1: What service do you have?

XHT: We provide turnkey solutions including PCB design, Software development, PCB Assembly, Enclosure design, Mold-making, Plastic injection, Finish product assembly, and function testing.

Q2: What are the main products of your PCB/PCBA services?

XHT: Our PCB/PCBA services are mainly for industries including Industrial control, Home appliances main boards, automotive electronics, Consumer electronics, Medical equipment, bank equipment, smart home, etc.

Q3: Is XHT a factory or trade company?

XHT: XHT is a 20-year experienced professional contract manufacturer to provides a stop Turnkey PCB assembly and electronics manufacturing service.

Q4: Can we inspect quality during production?

XHT: Yes, we are open and transparent on each production process with nothing to hide. Customers are welcome to inspect our production process and check in-house.

Q5: How can we ensure our information should not let the third party see our design?

XHT: We are willing to sign an NDA effect by customer side local law and promise to keep customers' data in high confidential level.

Q6: What files are required to get a quotation from you?

XHT: For OEM PCBA projects, please provide the Gerber data/files and an indication of related technical requirements as well as any special requirements if you have them; For ODM projects, please provide a Function List, so our engineering team can work on it.

Q7: What is the standard delivery term?

XHT: Delivery terms of EXW, FCA, FOB, DDU, etc. are all available based on each quote.

Q8: How long does it take for a PCBA quote?

XHT: Depends on the project's complexity. Normally 1-2 weeks is enough for our engineers to evaluate.

Q9: Do you have any minimum order quantity (MOQ) requirements?

XHT: No, we do not have MOQ requirements, we can support your projects starting from prototypes to mass productions.

Tell us your requirements about the FAQ by CLICKING HERE, so that we can provide a solution to save your budget and meet your needs!

![]()

![]()

![]()

![]()

![]()