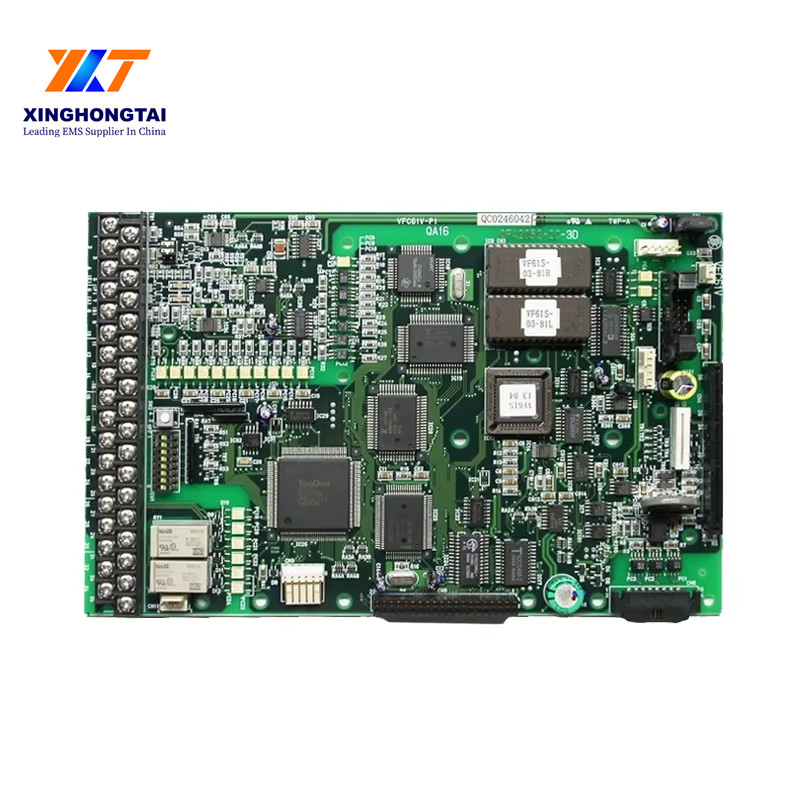

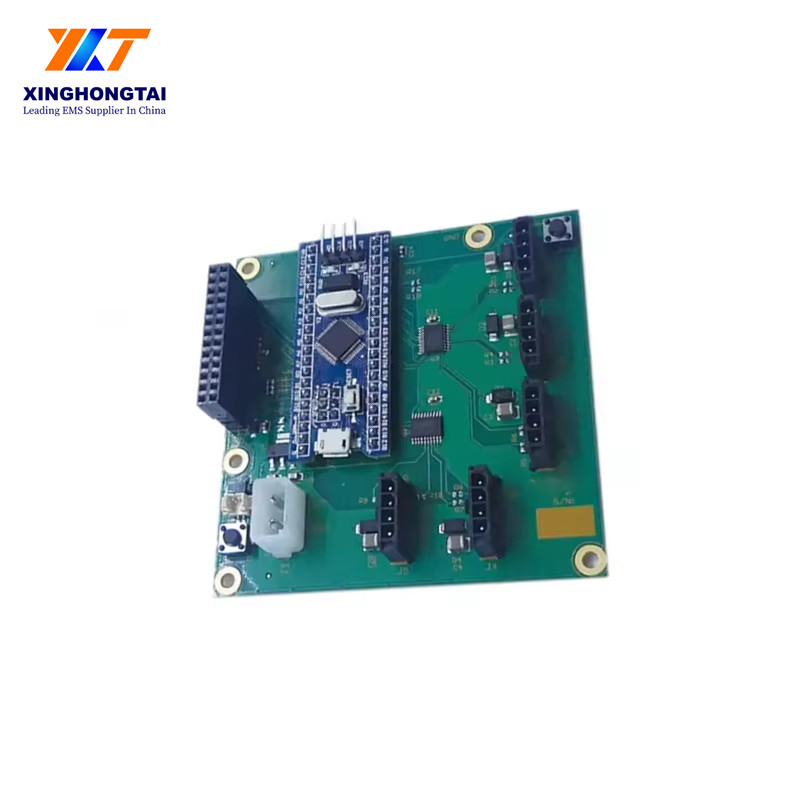

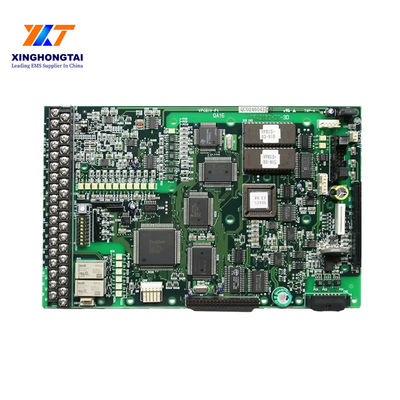

Performance Custom PCB Assembly with Smt Dip Support and Hard Gold Plated Surface

-

Highlight

Performance Custom PCB Assembly

,Smt Dip Support PCB Assembly

,Hard Gold Plated Surface PCB Assembly

-

Solder Mask ColorBlue.green.red.etc

-

Surface TechnicalHard Gold Plated

-

SurfaceHASL LF

-

Rows1 Or 2

-

LocationChina

-

LaminateFR4 High TG

-

CategarySMT PCBA Assembly

-

Trace4mil

Performance Custom PCB Assembly with Smt Dip Support and Hard Gold Plated Surface

Product Description:

Product Summary: Custom PCB Assembly

The SMT PCB Assembly product offers a versatile solution for various electronic manufacturing needs. With customizable features such as solder mask color, testing options, number of rows, production volume, and manufacturing location in China, this product is ideal for small to medium-scale production runs.

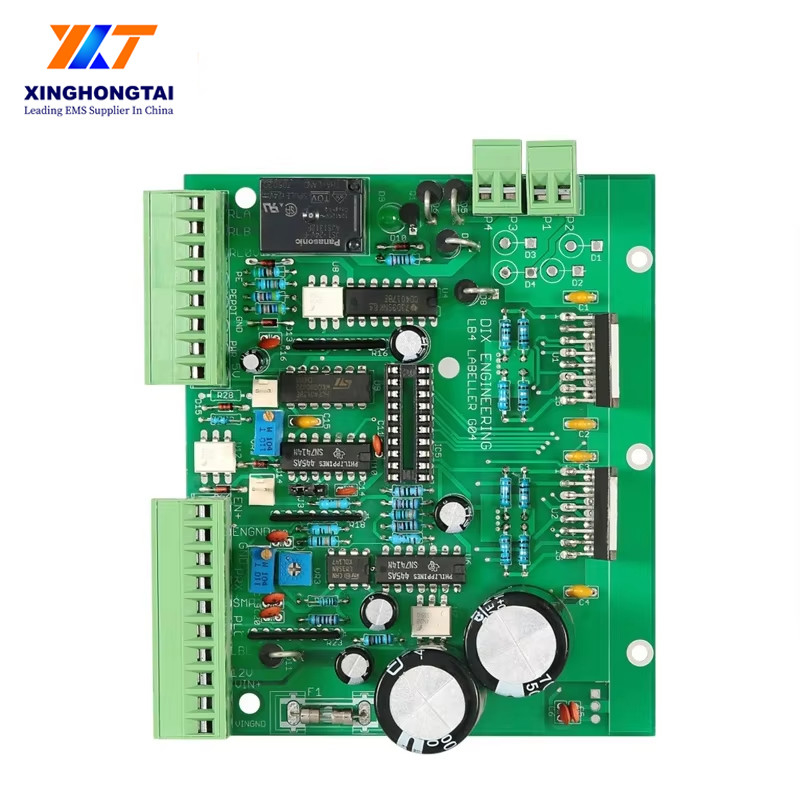

Solder Mask Color: Choose from a range of options including blue, green, red, and more to suit your design preferences and branding requirements. The solder mask color not only adds aesthetic appeal but also provides protection to the PCB components during the assembly process.

Testing: The SMT PCB Assembly product supports multiple testing methods including Flying Probe, In-Circuit Testing (ICT), and Functional Circuit Testing (FCT). These testing options help ensure the quality and reliability of the assembled PCBs, making it suitable for various industry applications.

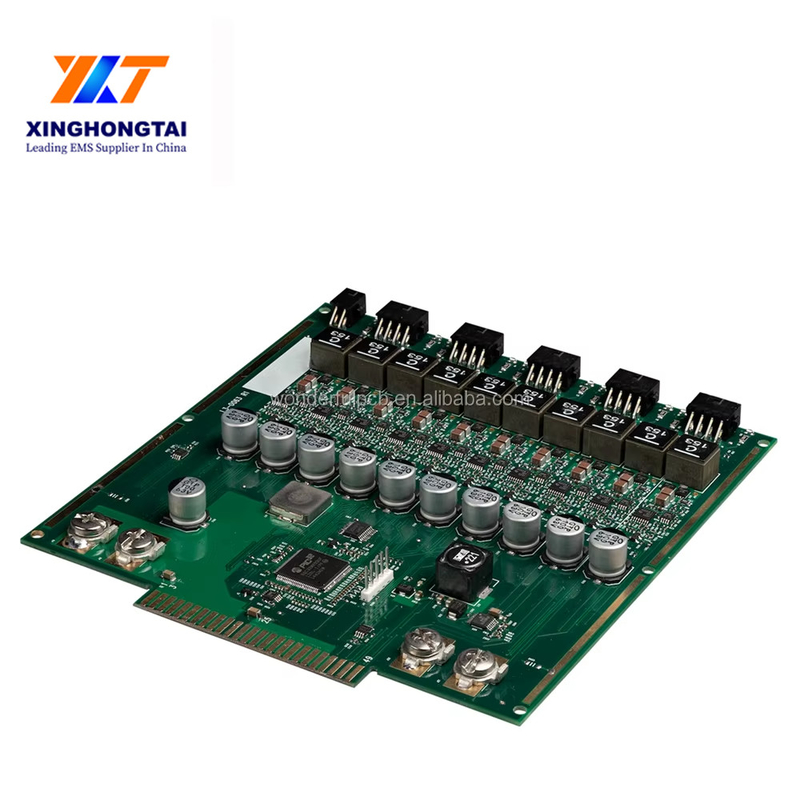

Rows: Select between 1 or 2 rows based on the complexity of your circuit design and layout requirements. The flexibility to choose the number of rows allows for customization according to your specific project needs, whether it is a simple or more intricate PCB design.

Location: The SMT PCB Assembly is manufactured in China, known for its advanced technology, skilled workforce, and cost-effective production capabilities. By choosing China as the manufacturing location, you benefit from high-quality assembly services while keeping production costs competitive.

Production Volume: This product is designed to accommodate small to medium production volumes, making it suitable for prototype development, small-scale projects, and medium-scale production runs. Whether you require a limited number of PCBs or a moderate production quantity, the SMT PCB Assembly product can meet your volume requirements.

Experience the benefits of Custom PCB Assembly with the SMT PCB Assembly product, offering customization options for solder mask color, testing methods, number of rows, production volume, and manufacturing location in China. Enhance the quality, reliability, and efficiency of your electronic manufacturing processes with this versatile and adaptable PCB assembly solution.

Features:

- Product Name: SMT PCB Assembly

- Trace: 4mil

- Rows: 1 Or 2

- Surface Treatment: ENIG

- Testing: Flying Probe/ICT/FCT

- Category: SMT PCBA Assembly

Technical Parameters:

| Surface Technical | Hard Gold Plated |

| Lead Time | 4 Working Days |

| Solder Mask Color | Blue, Green, Red, etc |

| Location | China |

| Category | SMT PCBA Assembly |

| Trace | 4mil |

| Laminate | FR4 High TG |

| Development Process | None, OEM Material |

| Rows | 1 or 2 |

| Surface | HASL LF |

Applications:

When it comes to custom PCB assembly, the SMT PCB Assembly product is a versatile solution that is suitable for a variety of product application occasions and scenarios. With a production volume ranging from small to medium, this product is ideal for businesses looking to manufacture electronics in quantities that are not too large.

One key feature of the SMT PCB Assembly product is its ability to accommodate a minimum hole size of 0.2mm (+/- 0.025), making it suitable for applications where precision is essential. This makes it a great choice for industries such as consumer electronics, automotive, medical devices, and more.

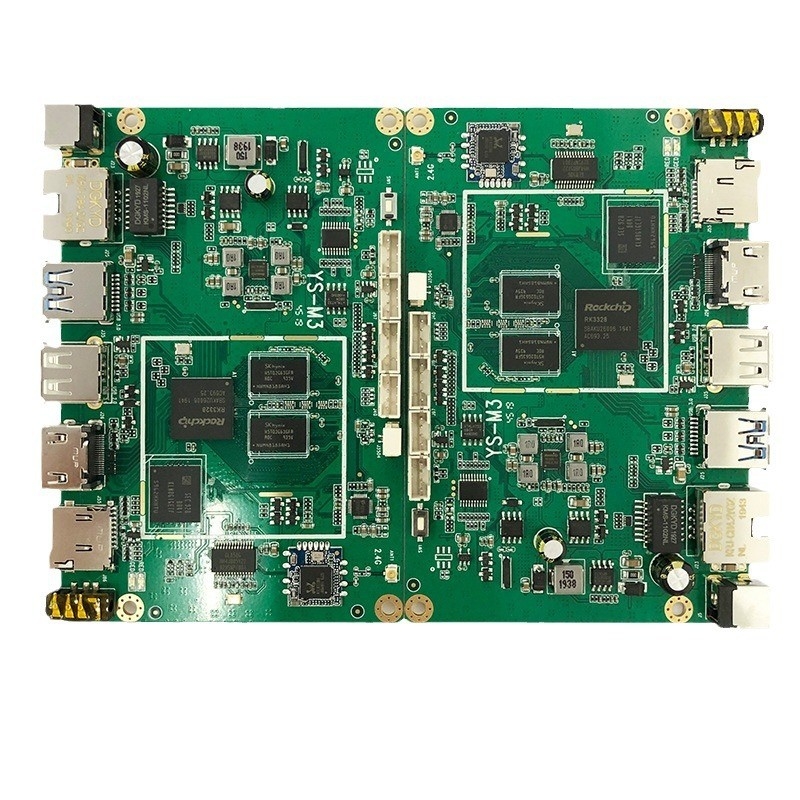

With a trace width of 4mil, the SMT PCB Assembly product offers high-density routing capabilities, allowing for complex circuit designs to be implemented with ease. This makes it perfect for applications that require intricate circuitry and compact PCB layouts.

The laminate material used in the SMT PCB Assembly product is FR4 High TG, which provides excellent thermal stability and reliability. This makes it suitable for applications where the PCB may be subjected to high temperatures or harsh environmental conditions.

Overall, the SMT PCB Assembly product is a top choice for businesses looking for a reliable and high-quality solution for custom PCB assembly. Whether you are working on a prototype or a medium-scale production run, this product offers the flexibility and performance needed to bring your electronics project to life.

Customization:

Custom PCB Assembly service for the SMT PCB Assembly product offers tailored solutions to meet your specific needs. Our customization options include:

- SMT Dip: Support

- Laminate: FR4 High TG

- Solder Mask Color: Blue, Green, Red, etc.

- Testing: Flying Probe/ICT/FCT

- Location: China

Support and Services:

The Product Technical Support and Services for the SMT PCB Assembly product include:

- On-site installation and setup assistance

- Remote troubleshooting and diagnostic support

- Periodic maintenance and software updates

- Training sessions for operators and maintenance personnel

Packing and Shipping:

Product Packaging: The SMT PCB Assembly product will be carefully packaged in anti-static bags to protect the delicate components from electrostatic discharge. It will then be placed in sturdy cardboard boxes with ample cushioning material to prevent any damage during transit.

Shipping: The SMT PCB Assembly product will be shipped via reliable courier services to ensure timely delivery. Customers can track their package using the provided tracking number. We take extra care to package the product securely to minimize the risk of damage during shipping.

FAQ:

Q: What is SMT PCB Assembly?

A: SMT PCB Assembly stands for Surface Mount Technology Printed Circuit Board Assembly. It is a method used in the electronics industry to mount electronic components directly onto the surface of a printed circuit board.

Q: What are the advantages of SMT PCB Assembly?

A: SMT PCB Assembly offers advantages such as smaller component sizes, higher component density, improved thermal performance, and cost-effectiveness compared to traditional through-hole assembly methods.

Q: What types of components can be used in SMT PCB Assembly?

A: SMT PCB Assembly supports a wide range of components, including resistors, capacitors, diodes, integrated circuits, connectors, and more. It is suitable for both passive and active components.

Q: What industries benefit from SMT PCB Assembly?

A: Industries such as consumer electronics, automotive, telecommunications, medical devices, and IoT devices benefit from SMT PCB Assembly due to its efficiency, reliability, and compact design capabilities.

Q: Can SMT PCB Assembly be customized for specific project requirements?

A: Yes, SMT PCB Assembly can be customized to meet specific project requirements, including component placement, board size, configuration, and assembly processes. This flexibility allows for tailored solutions to various applications.