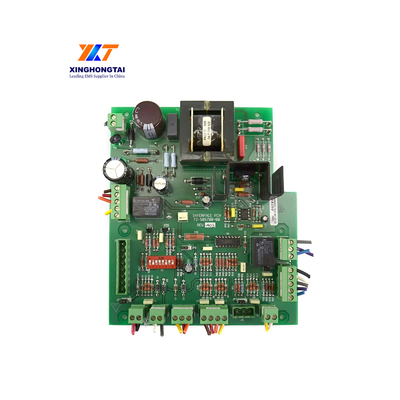

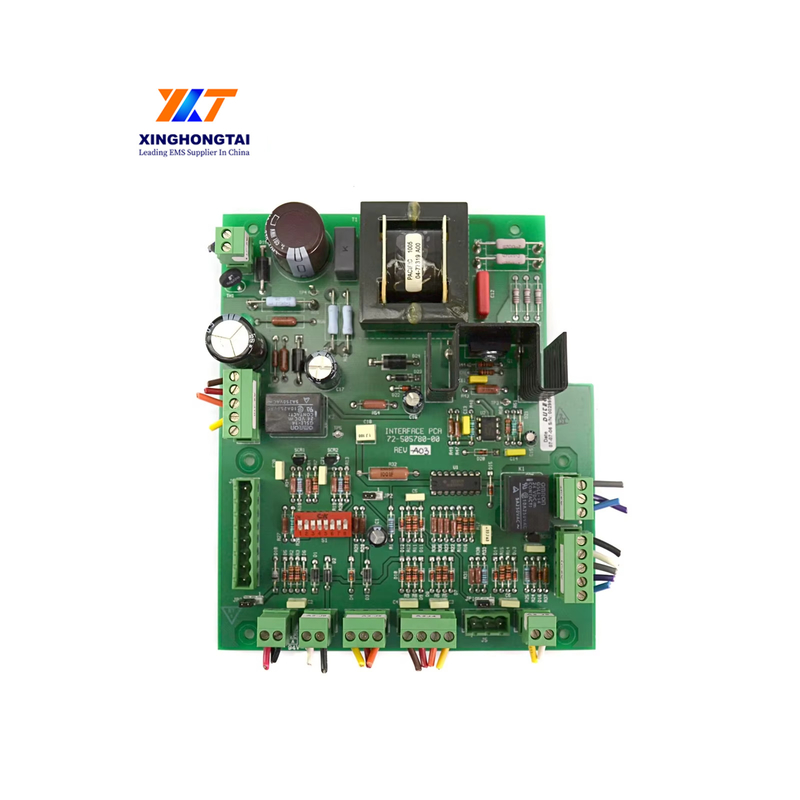

FR-4/High TG FR-4/CEM-3/M4/M6/Rogers Base Material PCBA for Industrial Control

-

Highlight

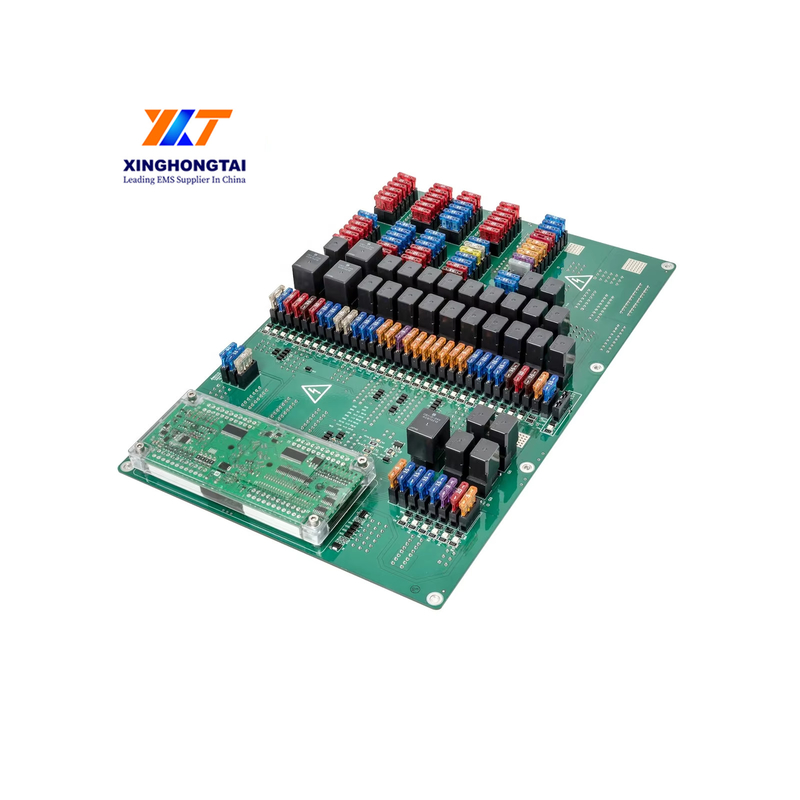

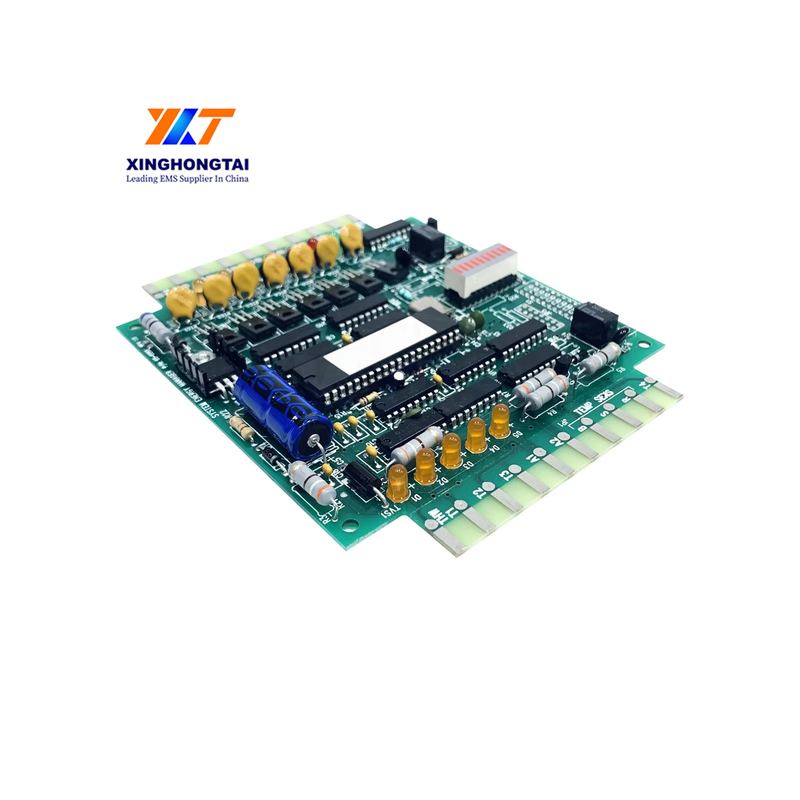

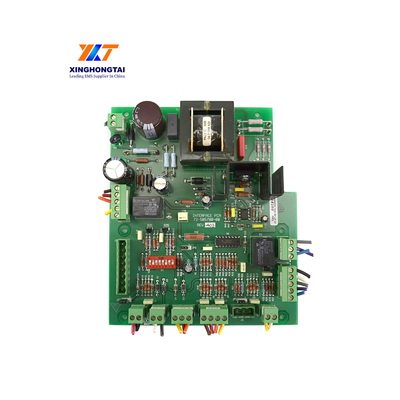

Industrial Control PCBA

,CEM-3 PCBA

,High TG FR-4 PCBA

-

Layer1-32 Layers

-

Functional ApplicationCircuit Protection

-

Copper Thickness1 OZ

-

Base MaterialFR-4/High TG FR-4/CEM-3/M4/M6/Rogers

-

Memory Bank2 DDR3 DIMM

-

Test Service100% E-testing

-

Operating Temperature0-70°C

-

Supplier TypeODM/OEM

-

CurrentCustomized

-

Board Thickness1.6MM

-

Place of OriginChina

-

Brand NameXHT

-

CertificationCE,RoHs,UL,FCC,ISO

-

Model NumberXHT-GR548

-

Minimum Order Quantity0

-

PriceUSD0.1-100/PCS

-

Packaging Detailsgreen energy brown packing, Eco friendly packing

-

Delivery Time5-8 work days

-

Payment TermsL/C, T/T

-

Supply Ability5000

FR-4/High TG FR-4/CEM-3/M4/M6/Rogers Base Material PCBA for Industrial Control

Product Description :

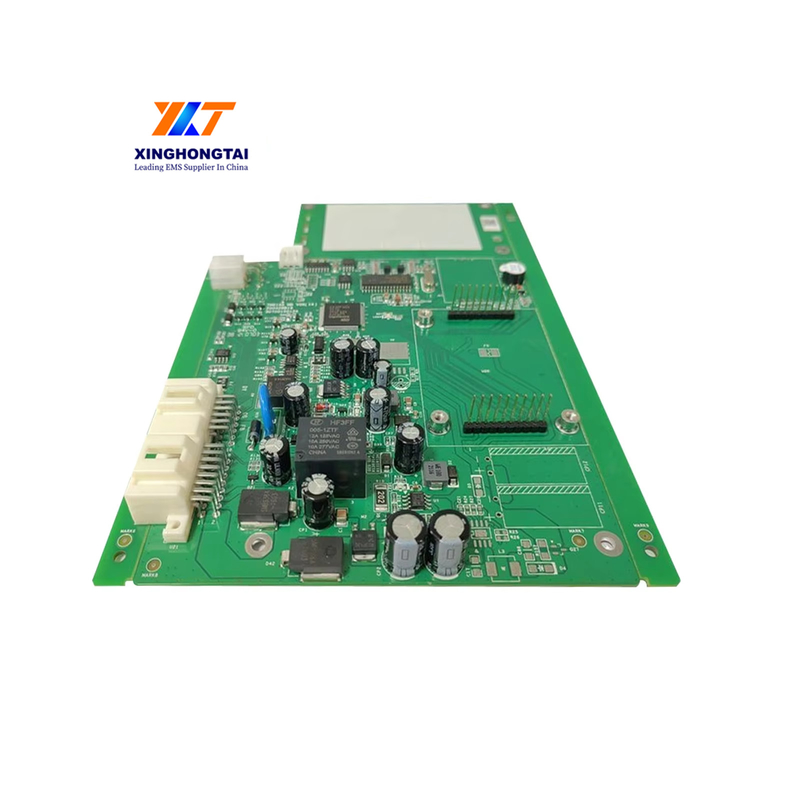

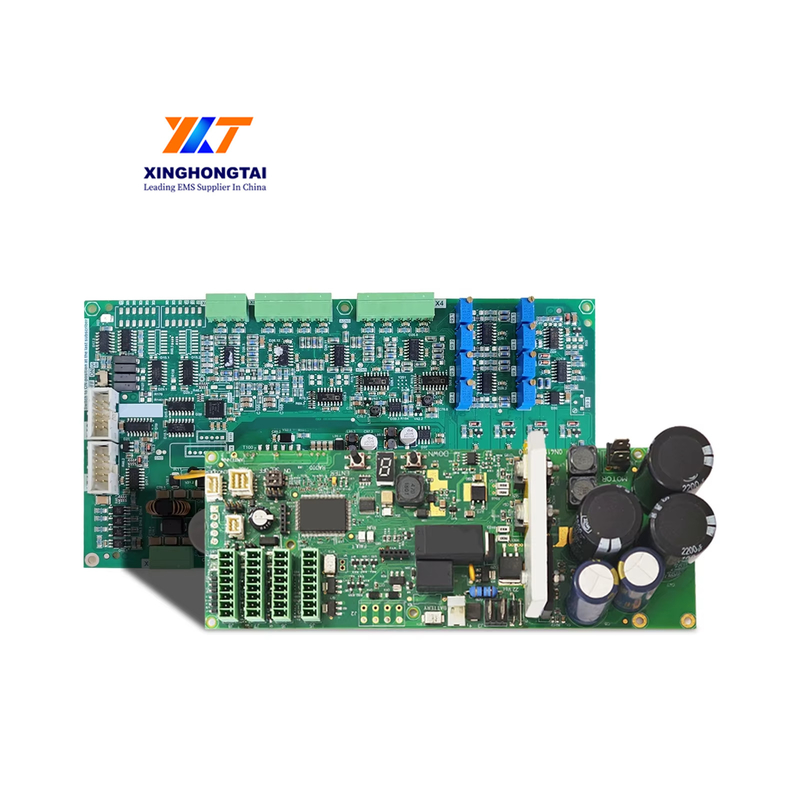

As a trusted OEM PCBA manufacturer for industrial control products, we deliver high-reliability printed circuit board assemblies tailored for industrial automation, machinery control, and energy management systems. Simply submit your Gerber files and BOM list, and we handle the entire process—component sourcing, SMT/DIP precision assembly, functional testing, and aging validation—ensuring compliance with industrial-grade demands (vibration resistance, wide-temperature operation, EMC immunity).

Utilizing IPC-A-610 Class 3 standards and specialized PCB techniques (heavy copper layers, high-TG materials), we support multi-layer boards, power modules, and complex interface designs. Rigorous AOI inspection, X-ray solder analysis, and FCT testing guarantee long-term stability in factory automation, PLC systems, and HMI devices. Offering rapid prototyping, low-volume flexibility, and mass production, we provide design-for-manufacturability (DFM) optimization to accelerate time-to-market and reduce supply chain risks!

![]()

XHT One-stop PCB PCBA Manufacturing includes the following aspects:

PCB Design: Providing PCB design services, including circuit design, layout, routing, and generating PCB design files.

PCB Manufacturing: Producing high-quality PCBs using advanced PCB manufacturing equipment and processes, including single-sided, double-sided, and multilayer boards.

Surface Treatment: Offering surface treatment options for PCBs, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), etc., to protect circuits and enhance solderability.

Component Procurement: Sourcing electronic components and devices from reliable suppliers based on PCBA design requirements.

PCBA Assembly: Assembling electronic components onto PCBs, completing the entire PCBA assembly process.

Testing and Quality Control: Implementing rigorous testing and quality control measures to ensure the performance and reliability of PCBA products.

Delivery and After-Sales Support: Delivering the finished PCBA products to clients and providing after-sales support to address any potential issues.

XHT One-stop PCB PCBA Manufacturing aims to provide clients with convenience, efficiency, and an integrated approach to complete the entire PCB and PCBA manufacturing process with a single supplier. This helps reduce communication and coordination costs and enhances project execution efficiency. By choosing XHT One-stop PCB PCBA Manufacturing, clients can focus on product development and market launch while ensuring a smooth manufacturing process and obtaining high-quality, reliable, and cost-effective PCBA products.

| SMT Lines | 12 Lines |

| Capacity | 60.2 Million Placements Per Month |

| Component Board | Max:550*450MM Min:50MM*50MM |

| Speed | 0.15sec/chip 0.7sec/QFP |

| Wave- Solder | |

| Max. PCB width: 550MM*450 MM;Min:50MM*50MM | Component height: Top 120 mm/Bot 15 mm |

| DIP Capacity | 420 square meters per hour |

| Plug-in Equipment | PTH (Printed Through Hole) Machine. Non-standard Surface Mount Technology (SMT) Machine |

| Components | Passives Down to 0201 Size BGA and VFBGA Leadless Chip Carrier/CSP Double-Sided SMT Assembly Fine Pitch to 08 Mil BGA Repair and ReballPart Removal and Replacement-Same Day Service |

| Test Equipment | FAI, X-RAY, SPI, ICT, FCT, AOI, 3D AOI, Burn-in, High-temperature Load |

| Box Build | Box Build Integration and Assembly |

| Quotation Document | Bill of Materials, Gerber Files, Pick-N-Place File(XYRS) |

| Turn Time | 10 day Service to 30 Day Service |

| Quantity | No MOQ, Prototype PCB Assembly & Small Batch PCB Assembly & Wholesale PCBAS |

![]()

![]()

![]()

Product Packaging:

The EMS PCB Assembly product will be packaged securely in anti-static bags and placed in a sturdy cardboard box with protective foam inserts.

Shipping:

We offer worldwide shipping for the EMS PCB Assembly product. Shipping options include standard, expedited, and express delivery. Customers can choose their preferred shipping method during the checkout process.

All shipments will be tracked and customers will receive a tracking number once the product has been shipped. Shipping fees will be calculated at checkout based on the destination and selected shipping method.

FAQ:

Q1: What service do you have?

XHT: We provide turnkey solutions including PCB design, Software development, PCB Assembly, Enclosure design, Mold-making, Plastic injection, Finish product assembly, and function testing.

Q2: What are the main products of your PCB/PCBA services?

XHT: Our PCB/PCBA services are mainly for industries including Industrial control, Home appliances main boards, automotive electronics, Consumer electronics, Medical equipment, bank equipment, smart home, etc.

Q3: Is XHT a factory or trade company?

XHT: XHT is a 20-year experienced professional contract manufacturer to provides a stop Turnkey PCB assembly and electronics manufacturing service.

Q4: Can we inspect quality during production?

XHT: Yes, we are open and transparent on each production process with nothing to hide. Customers are welcome to inspect our production process and check in-house.

Q5: How can we ensure our information should not let the third party see our design?

XHT: We are willing to sign an NDA effect by customer side local law and promise to keep customers' data in high confidential level.

Q6: What files are required to get a quotation from you?

XHT: For OEM PCBA projects, please provide the Gerber data/files and an indication of related technical requirements as well as any special requirements if you have them; For ODM projects, please provide a Function List, so our engineering team can work on it.

Q7: What is the standard delivery term?

XHT: Delivery terms of EXW, FCA, FOB, DDU, etc. are all available based on each quote.

Q8: How long does it take for a PCBA quote?

XHT: Depends on the project's complexity. Normally 1-2 weeks is enough for our engineers to evaluate.

Q9: Do you have any minimum order quantity (MOQ) requirements?

XHT: No, we do not have MOQ requirements, we can support your projects starting from prototypes to mass productions.

Tell us your requirements about the FAQ by CLICKING HERE, so that we can provide a solution to save your budget and meet your needs!

![]()

![]()

![]()