Solar Inverter Circuit Board PCB Manufacturer Multilayer PCBA Assembly

-

Place of OriginChina

-

Brand NameXHT

-

CertificationCE, RoHs, UL, UKCA, SAA, REACH, FCC

-

Model NumberXHT20250609

-

Minimum Order Quantity1

-

Price0.6-10 dollars

-

Packaging Detailsgreen energy brown packing, Eco friendly packing

-

Delivery Time5-8 working day

-

Payment TermsT/T

-

Supply Ability50000

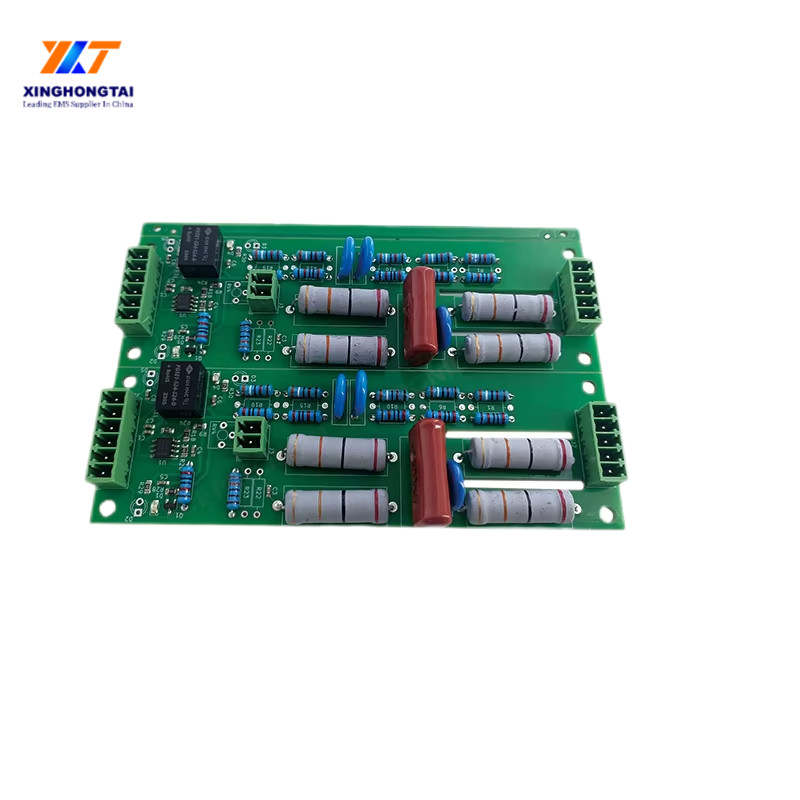

Solar Inverter Circuit Board PCB Manufacturer Multilayer PCBA Assembly

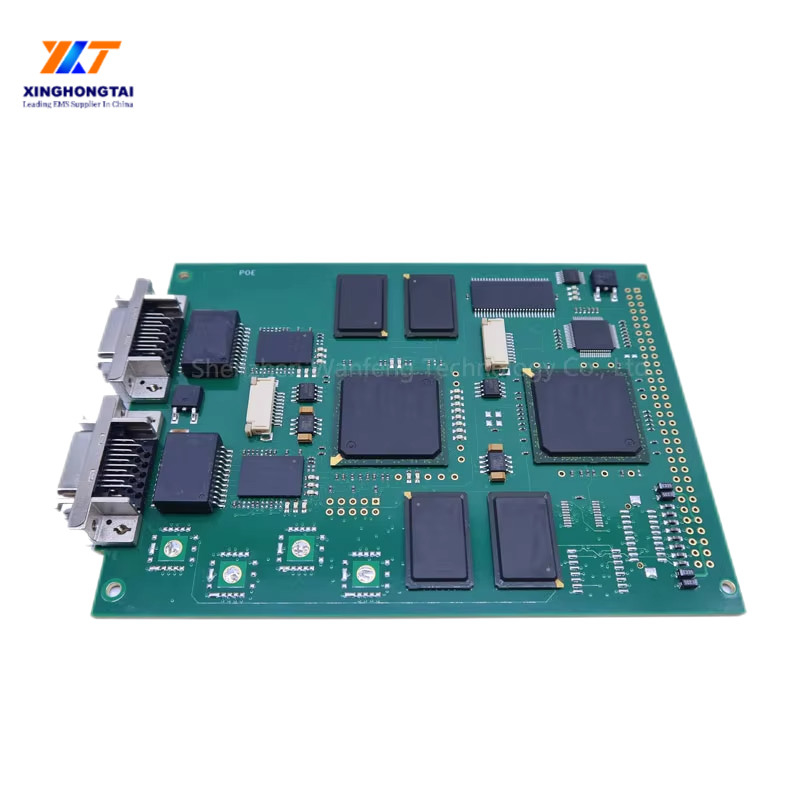

PCBAs (Printed Circuit Board Assemblies) have various applications in the field of new energy. Here are some key areas:

Solar Energy: PCBAs play a crucial role in the production of solar panels. They are used to control the current and voltage of photovoltaic arrays and convert solar energy into electricity.

Wind Energy: In wind turbines, PCBAs are used to control the rotation speed of the blades, monitor parameters such as temperature and wind speed, and maximize the efficiency of the generator.

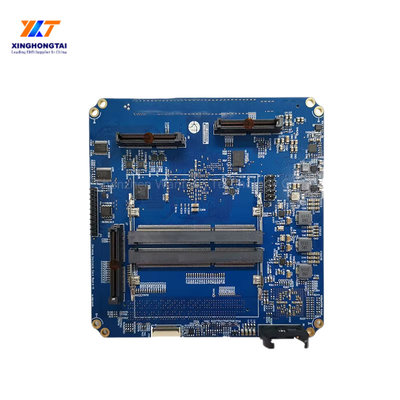

Electric Vehicles: PCBAs are utilized in the electronic control units (ECUs) and battery management systems (BMS) of electric and hybrid vehicles. They control the motor, monitor battery status, manage energy flow, etc.

Energy Storage Systems: PCBAs are essential components of energy storage systems such as battery packs and supercapacitors. They are used for monitoring energy flow, protecting batteries from overcharging and over-discharging, etc.

Smart Grids: In smart grids, PCBAs are employed for controlling energy distribution and management. They can be used for monitoring power loads, optimizing power transmission, and enabling remote monitoring.

Energy Management Systems: PCBAs are widely used in various energy management systems, including energy monitoring systems, energy optimization systems, etc. They collect data, implement control strategies, and communicate with other systems.

In summary, PCBAs have broad applications in the field of new energy, covering various aspects from energy production to storage and utilization.

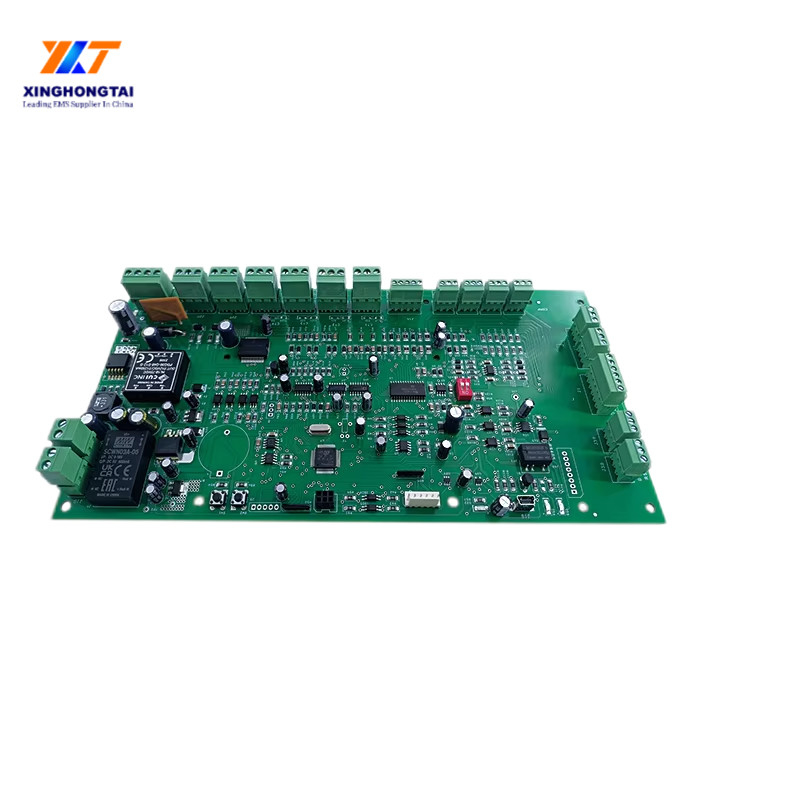

Battery Safety Starts with One Thing: Cell + BMS Compatibility

In C&I (commercial and industrial) energy storage systems, the most critical safety factor is often underestimated:

Cell and BMS matching.

Even with high-end BMS units and top-tier cells, system failures still happen—why?

Because incompatibility in electrical and chemical characteristics can lead to thermal runaway, inaccurate SoC/SoH readings, or premature degradation.

Each type of cell behaves differently in terms of:

a. Internal resistance

b. Self-discharge rate

c. Temperature response

d. Aging pattern

A universal BMS may not be able to track or manage these variables accurately without careful tuning and validation.

In our experience, the number one root cause of safety issues in energy storage projects is poor BMS-cell matching, especially in large-scale or high-power applications.

Have you encountered such problems in your projects?

What’s your approach to verifying cell-BMS compatibility before deployment?

Would love to exchange insights on testing methods, long-term validation strategies, or lessons learned.

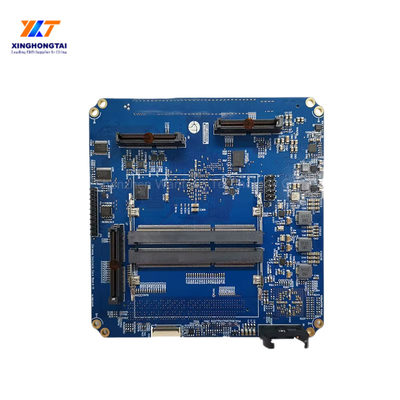

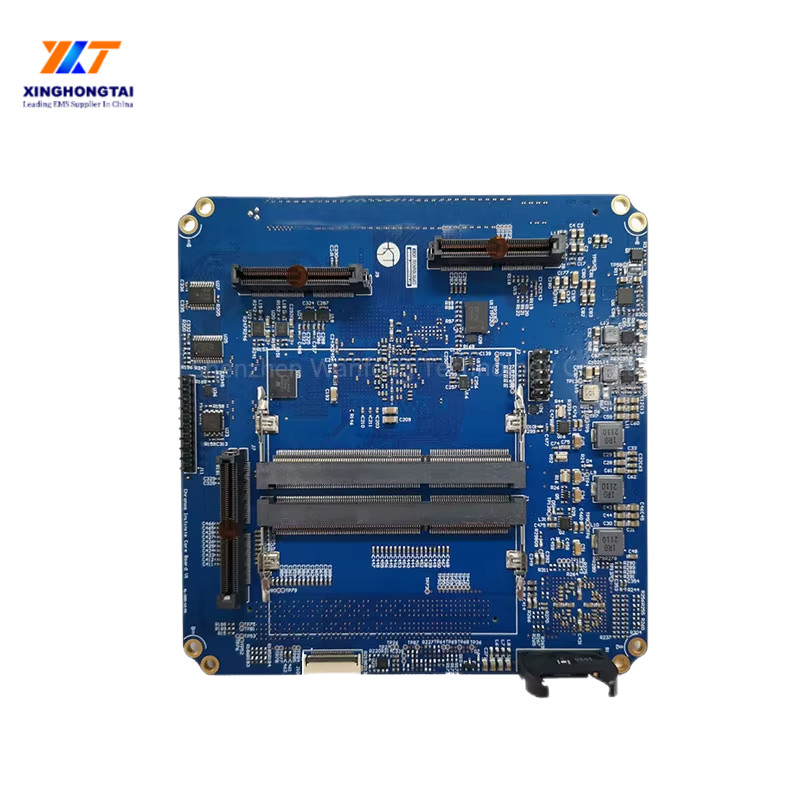

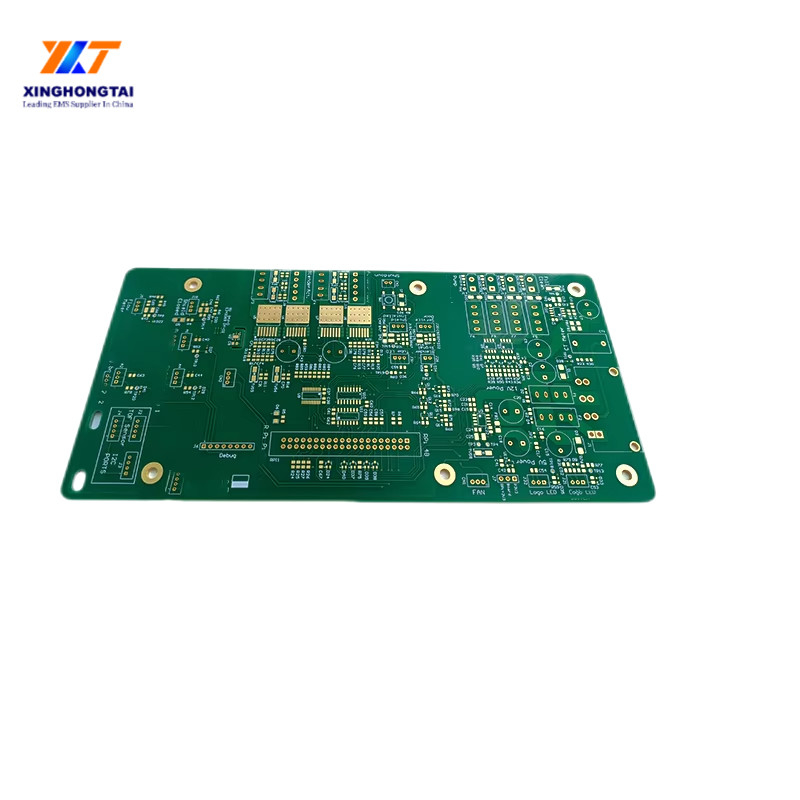

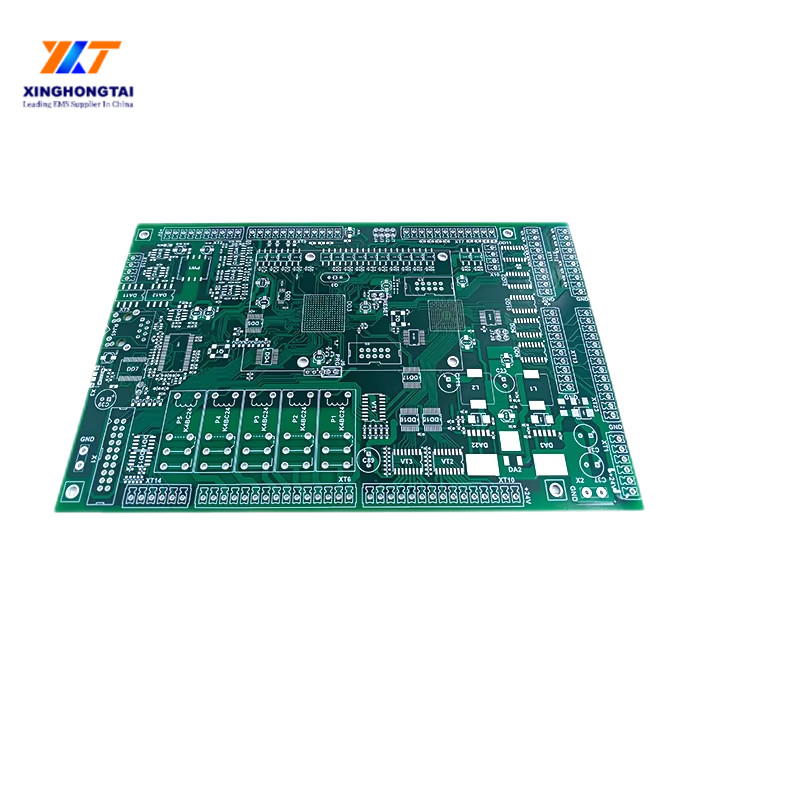

Multilayer PCB Specification Table

| Attribute | Details |

|---|---|

| Model Number | XHT20250609 |

| Type | Multilayer PCB |

| Place of Origin | Guangdong, China |

| Brand Name | OEM / ODM Available |

| Number of Layers | 1–40 Layers |

| Board Thickness | Standard: 1.6mm (Custom: 0.2–7.0mm) |

| Board Size | Customized (Please contact us) |

| Base Material | FR4 |

| Copper Thickness | Standard: 1oz (Finished: 1–6oz) |

| Min. Hole Size | 0.2mm |

| Min. Line Width / Spacing | 0.1mm / 0.1mm |

| Hole Tolerance | PTH: ±3mil, NPTH: ±2mil |

| Surface Finish | Immersion Gold |

| Solder Mask Colors | Green, Blue, Black, Red, Yellow, White |

| Impedance Control Tolerance | ±5% |

| PCB Standard | IPC-A-610 D |

| Certificate | ISO, RoHS |

| OEM/ODM Service | One-stop turnkey solution |

| Small Order | Acceptable |

Packaging & Delivery

| Item | Details |

|---|---|

| Packaging for PCB | CNC-secured packaging |

| Packaging for PCBA | ESD packaging with POE box |

| Port of Dispatch | Shenzhen |

| Selling Unit | Single item |

| Package Size | 1 × 0.8 × 0.4 cm |

| Gross Weight | 0.5 kg |

![]()

![]()