-

Highlight

Mixed Technology Quick Turn Assembly

,ODM Quick Turn Assembly

,Mixed Technology Quick Turn PCB

-

Product NameQuick Turn PCB Assembly Service OEM ODM

-

FeatureOEM And ODM

-

SMT Production Line12

-

High-end EquipmentFUJI NXT3/XPF Laminator

-

MaterialFR4/M4/M6/Rogers/TU872/IT968

-

TestAOI/SPI/XRAY/First Article Inspection

-

Place of OriginCHINA

-

Brand NameXHT

-

CertificationCE、RoSH、ISO

-

Model NumberXHT Quick Turn PCB Assembly-2

-

Minimum Order Quantity1k

-

Packaging DetailsCarton with foam bag

-

Delivery Time5-8 work days

-

Payment TermsT/T, Western Union, MoneyGram

Advanced Technology Quick Turn PCB Assembly OEM ODM Acceptable

Quick Turn PCB Assembly Service OEM ODM

What is circuit board assembly?

Printed circuit board assembly is the process of connecting the electronic components with the wirings of printed circuit boards. The traces or conductive pathways engraved in the laminated copper sheets of PCBs are used within a non-conductive substrate in order to form the assembly. Attaching the electronic components with the printed circuit boards is the concluding action before using the fully operational electronic device

Satisfied Services

1. 7/24 Sales and technical support

2. Felxible payment methods and negotiable payment terms

3. Both samples and bulk orders are supported

4. More than 10 years overseas export experience, flexible handling of transportation and customs clearance issues

Strengths of XHT

- ICT(In Circuit Test),FCT(Functional Circuit Test) technology

- PCB Assembly service With CE, FCC, Rohs Approval

- Nitrogen gas reflow soldering technology for SMT

- Technical Requirement for PCB Assembly service

- Professional Surface-mounting and Through-hole soldering Technology

- Various sizes like 1206, 0805, 0603 components SMT technology

- High Standard SMT&Solder Assembly Line

- High density interconnected board placement technology capacity

Technical Requirement for PCB Assembly

- Professional Surface-mounting and Through-hole soldering Technology

- Various sizes like 1206, 0805, 0603 components SMT technology

- ICT(In Circuit Test), FCT(Functional Circuit Test) technology

- High Standard SMT&Solder Assembly Line

- High density interconnected board placement technology capacity

- PCB Assembly service With CE, FCC, Rohs Approval

- Nitrogen gas reflow soldering technology for SMT

Specification

| NO. | Items | Capabilities |

| 1 | Layers | 2-68L |

| 2 | Maximum machining size | 600mm*1200mm |

| 3 | Board thickness | 0.2mm-6.5mm |

| 4 | Copper thickness | 0.5oz-28oz |

| 5 | Min trace/space | 2.0mil/2.0mil |

| 6 | Minimum finished aperture | 0. 10mm |

| 7 | Maximum thickness to diameter ratio | 15:1 |

| 8 | Via treatment | Via, blind&buried via, via in pad, Copper in via … |

| 9 | Surface finish/treatment | HASL/HASL lead free, Chemical tin, Chemical Gold, Immersion gold Inmersion Silver/Gold, Osp, Gold Plating |

| 10 | Base Material | FR408 FR408HR, PCL-370HR;IT180A, Megtron 6(Panasonic);Rogers4350, Rogers4003, RO3003, Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| 11 | Solder mask color | Green.Black.Red.Yellow.White.Blue.Purple.Matte Green. Matte Black |

| 12 | Testing Service | AOI, X-Ray, Flying-Probe, Function Test, First Article Tester |

| 13 | Profiling Punching | Routing,V-CUT,Beveling |

| 14 | Bow&twist | ≤0.5% |

| 15 | HDI type | 1+n+1,2+n+2,3+n+3 |

| 16 | Min mechanical aperture | 0.1mm |

| 17 | Min laser aperture | 0.075mm |

Company Descripiton

XHT with customers to provide them with the highest-quality PCB and PCB Assembly service electronic manufacturing services to achieve their goals. Our flexibility is in meeting customer requirements and our superior customer service. We help companies introduce their new products to market in the fastest time possible by providing high quality, quick-turn assembly. We provide one-stop electronic manufacturing service to help you qualify your designs and provide quality samples to your customers.

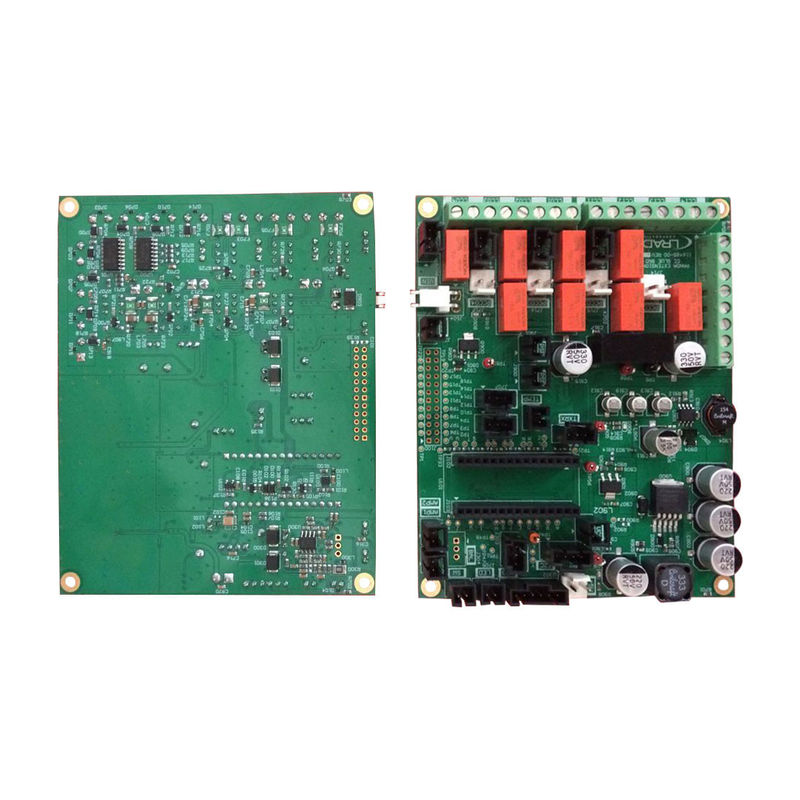

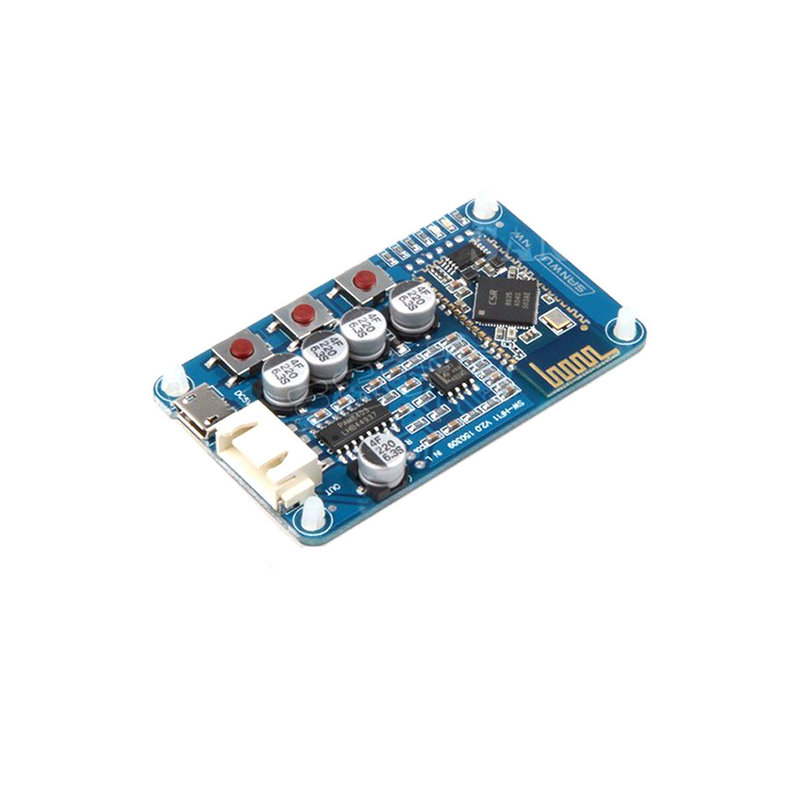

![]()

![]()

![]()

![]()

FAQ

| Q: What service do you have? XHT: We provide one-stop solutions including PCB manufacturing, SMT, component sourcing, final assembly, testing and other services. |

| Q: What is needed for PCB & PCB Assembly quotation? XHT: For PCB: Gerber file and technic requirements(material,size, surface finish treatment, copper thickness,board thickness) and quantity you need. For PCB Assembly: Files mentioned above, BOM, pick and place file. |

| Q: Are my files safe? XHT: Your files are held in complete safety and security.We protect the intellectual property for our customers in the whole process.. All documents from customers are never shared with any third parties. If requested by the client, we will sign an NDA subject to local laws on the client's side and promise to keep client data highly confidential. |

| Q: What are the main products of your PCB/PCB Assembly services? XHT: Automotive, Military, Aerospace, Industry Control, Medical care, IOT, Smart Home, Robot, Auto parts, Camera, UAV. |