Electric Outboard Motors PCBA OEM Custom PCB PCBA Board PCB Box Build Assembly SMT DIP

-

Highlight

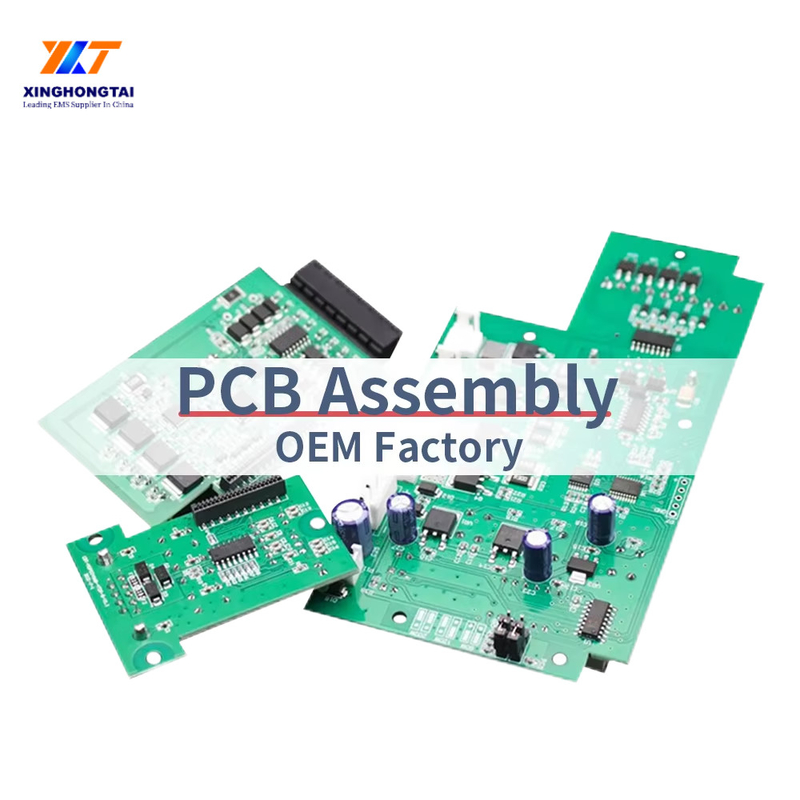

Electric outboard motors PCBA

,SMT DIP PCB Box Build Assembly

,OEM custom PCB PCBA

-

CertificateISO、IATF16949、RoSH

-

Copper Thickness1 OZ

-

Surface FinishingHASL;Flash Gold,Plated Silver

-

Board Thickness0.1-2.0mm

-

Testing Service100% AOI ICT LCT FCT Testing

-

ApplicationElectric Outboard Motors

-

ServiceOne-stop Turnkey PCBA Service

-

MOQ1PCS

-

Place of OriginChina

-

Brand NameXHT

-

CertificationCE,RoHs,UL,FCC,ISO

-

Model NumberXHTCT12

-

Minimum Order Quantity10

-

PriceUSD1-100/PCS

-

Packaging Detailsgreen energy brown packing, Eco friendly packing

-

Delivery Time5-8 work days

-

Payment TermsL/C, T/T

-

Supply Ability5000

Electric Outboard Motors PCBA OEM Custom PCB PCBA Board PCB Box Build Assembly SMT DIP

Innovative Power Management in Water Scooters: Lithium Batteries, BMS, and PCBA Technology

As the demand for eco-friendly, high-performance water scooters rises, integrating Lithium Battery Systems, Battery Management Systems (BMS), and Printed Circuit Board Assemblies (PCBA) is crucial for maximizing performance, safety, and longevity.

![]()

Who We Are

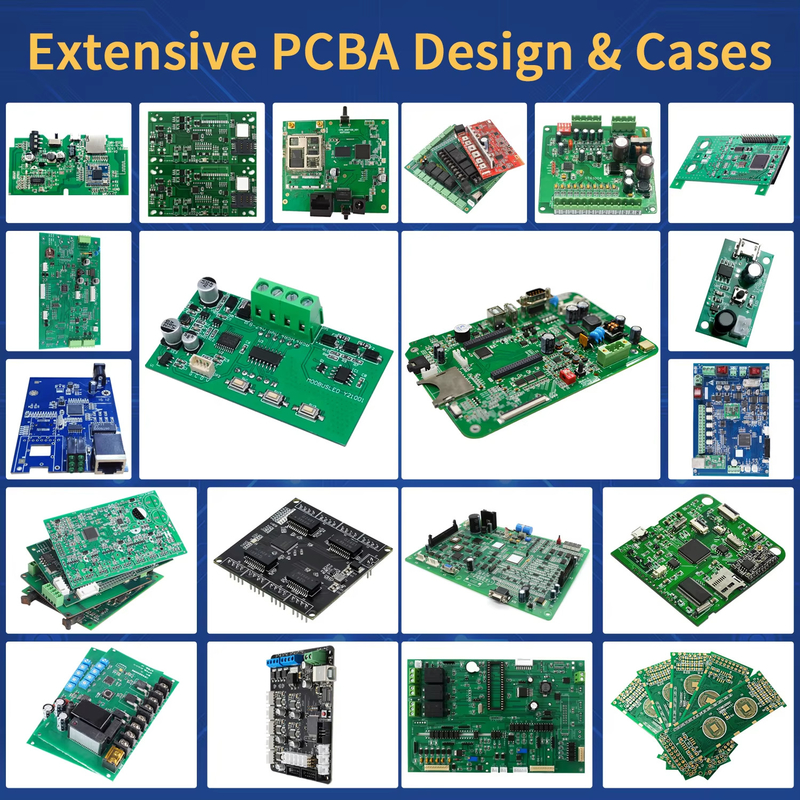

XHT is an All-in-One solution provider for the fabrication of high-reliability, multi-layer, complex boards. Our PCBA services include supply chain management, assembly, test & inspection, rework, and NPI (New Product Introduction). The combination of our experience since 2004 in PCB & PCBA provision serves as a solid base for miniaturization solutions, which include organic substrates and advanced packaging.

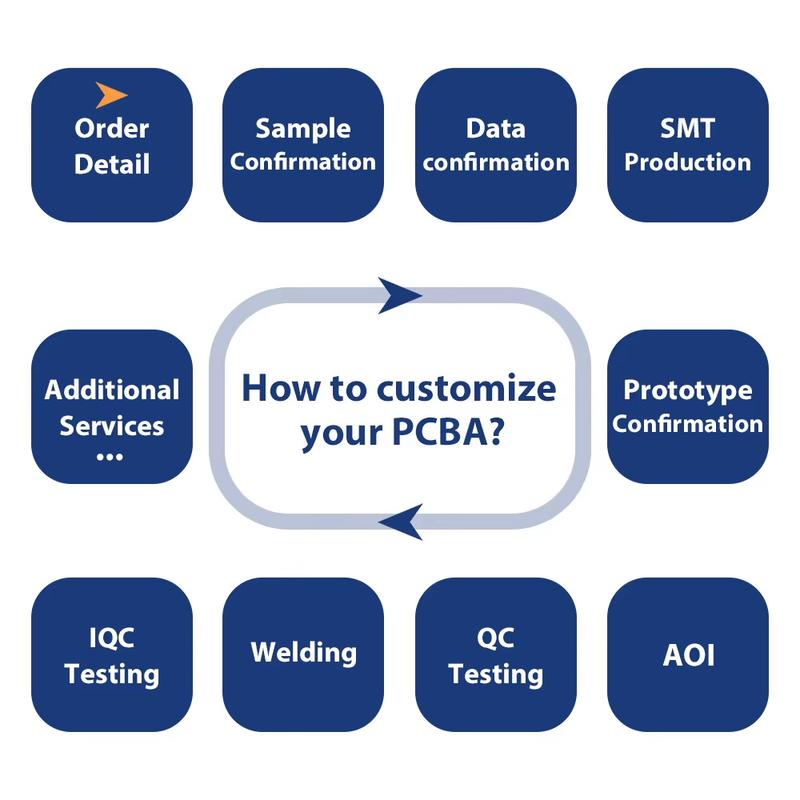

What We Do

Our highly experienced team, state-of-the-art technologies, and advanced processes enable us to deliver innovative and complete solutions. All this while ensuring cost-effectiveness in a global network supply chain. A can-do attitude and a heterogeneous engineering approach are how we operate. This makes manufacturers’ reliance on multi-vendor operations redundant. Our common design rules throughout the design and fabrication stages minimize the need for compromise on off-the-shelf products, allowing us to develop innovative ones instead.

On-time delivery

Meet all order requirements from Prototypes to volumes

ON TIME, EVERY TIME.

Quality assurance

Comply with ISO, IATF, UL standards, Online SPI, AOI, X-Ray inspection equipment, 99.5% pass rate of product delivery.

Professional team

Expert Stackup team and 40+ High precision CAM editor team. We are not only experienced but highly qualified.

Quick Response Service

We will respond to your enquiries and share the quotation within

12 hours.

ADVANCED MANUFACTURING CAPABILITIES

| Process / Technology | Details |

| Fuji-Nxt – Multiple SMT Lines | Single and Double Sided Selective Wave |

| IPC 610 Class 2 & 3 Assembly | Quartz Crystal Processing |

| Clean & No-Clean Process | Thick / Thin Film Microelectronics |

| PBGA (PITCH BALL GRID ARRAY) | FBGA (FINE BALL GRADE ARRAY) to 0.5mm |

| High Melting Point Solder | Chip-on-Board / Wire Bond / Chip on chip |

| HMLV (High-Mix Low-Medium-Volume) PCB Assembly | Through Hole & SMT Mixed |

| Through Hole to SMT Conversion | Complete End Product Assembly |

| Avionics LRU Assembly | Leadless Chip |

| Overflow Assembly | Fine Pitch (0201 & 01005) |

| Box Build / Final Assembly / System Integration | Multi-Chip Modules |

| In-Circuit & Functional Testing | Conformal Coating - Automated and Manual |

| BGA Rework | Automated Cleaning Solutions |

| Hotplate Soldering | Potting |

| Track Cutting & Additive Pad Fixing | Flex Rigid PCB Assembly & Test |

| RF & Microwave – Assembly & Test | Hot Plate Soldering |

TEST CAPABILITIES

| In circuit Test – HP & Teradyne | BGA Rework Stations |

| Flying Probe Tester (Takaya) | Environmental Stress & Screening (ESS) – Active & Passive |

| 2D&3D Automatic XRAY Inspection | Functional Test Design, Development, Management |

| Automatic Optical Inspection | Diagnostic Test |

| Automatic Solder paste inspection | Firmware & System Test |

| Synod & DITMICO cable test | Calibration |

| Multiple JTAG test systems | NI & Key sight ATE |

| Boundary Scan | Reverse engineering |

| High Voltage & Insulation Testing |

CERTIFIED TEST &SCREENING FACILITY

| He / FC Bombing | Liquid Thermal Shock |

| Internal / External Visual Inspection | Thermal Humidity Bias Test |

| Fine & Gross Leak Testers | Burn in Chambers |

| Temperature Cycling (-65 to 200 deg C) | 3.5 Ton Vibration |

| Constant Acceleration | Thermal Vacuum Chamber |