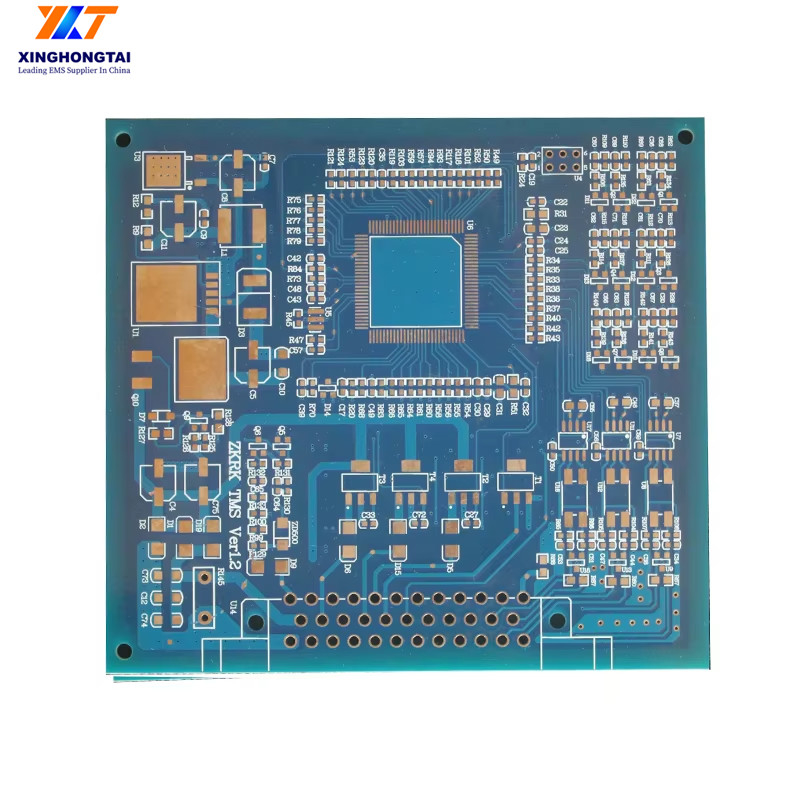

Military-Grade PCBA for Aerospace Applications Rugged Shockproof High-Precision Circuit Board for Defense Communication Avionics

-

Highlight

Military-Grade PCBA

,High-Precision PCBA

,Rugged Shockproof PCBA

-

Base MaterialFR-4/High TG FR-4/CEM-3/M4/M6/Rogers

-

Supplier TypeOEM&ODM

-

Copper Thickness1oz

-

Material TypeFR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers

-

Solder MaskGreen/Yellow/Black/White/Red/Blue

-

Product NameAerospace PCBA

-

Functional ApplicationNavigation

-

ApplicationCommunications, Industrial Electronic,medical

-

Place of OriginChina

-

Brand NameXHT

-

CertificationCE,RoHs,UL,FCC,ISO

-

Model NumberXHTYY-001

-

Minimum Order Quantity0

-

PriceUSD0.01-100/PCS

-

Packaging Detailsgreen energy brown packing, Eco friendly packing

-

Delivery Time5-8 work days

-

Payment TermsL/C, T/T

-

Supply Ability5000

Military-Grade PCBA for Aerospace Applications Rugged Shockproof High-Precision Circuit Board for Defense Communication Avionics

product Introduction

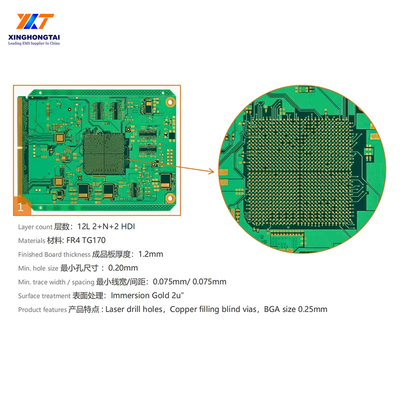

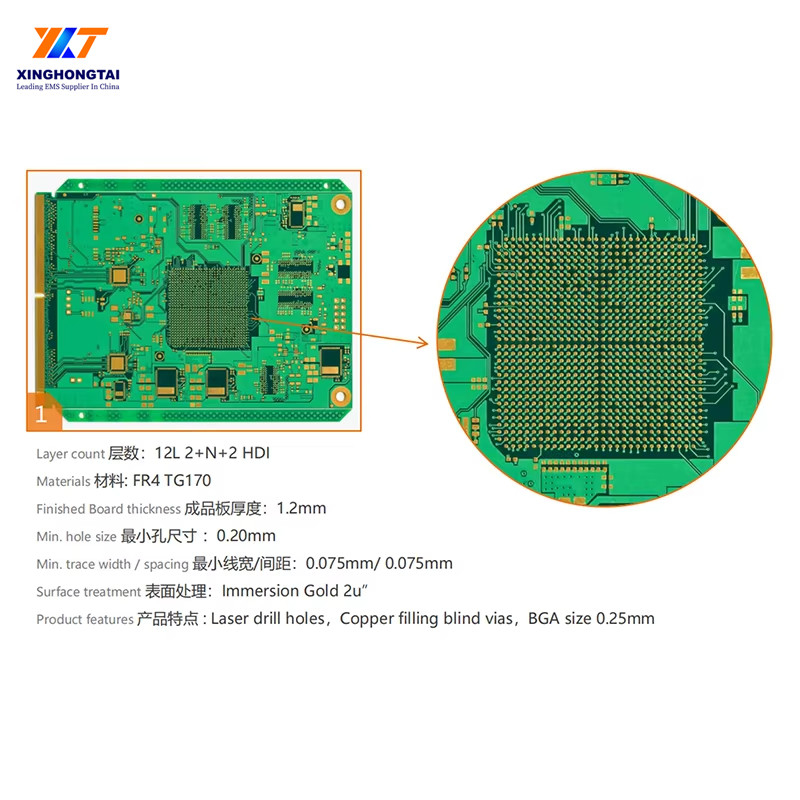

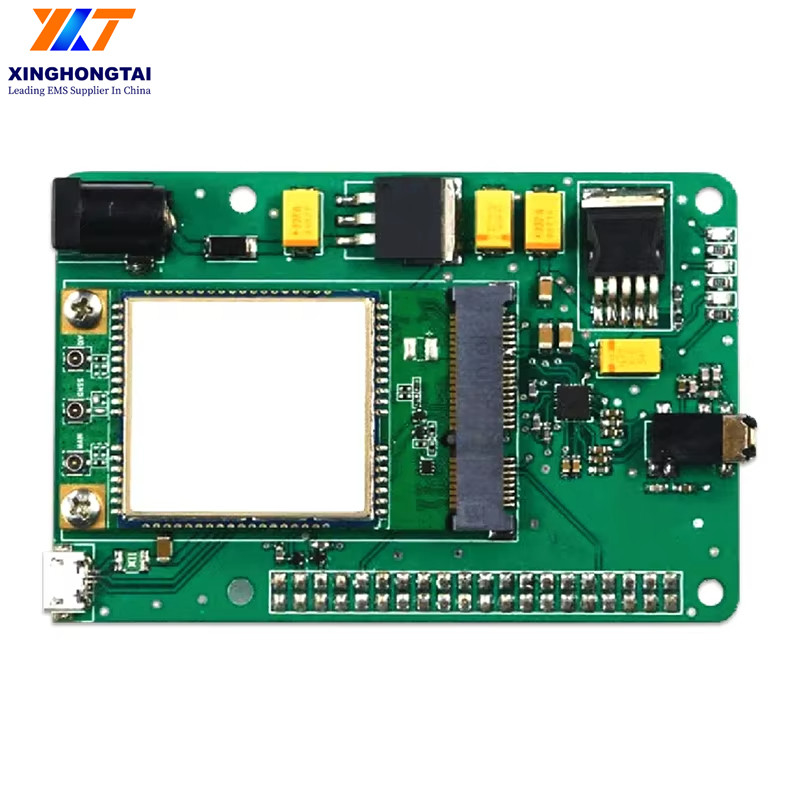

Our military-grade PCBA (Printed Circuit Board Assembly) is designed for aerospace applications, especially for defense communications and avionics systems that require high reliability, shock resistance and precise performance. Here are the main features and benefits of this product:

Main Features

1.Military-grade design standards

Meet MIL-STD specifications:

- Strictly follow the MIL-STD-810G environmental test standard to ensure stable operation under extreme temperature, humidity, vibration and shock conditions.

- Meet the MIL-STD-461 electromagnetic compatibility (EMC) requirements to ensure the electromagnetic compatibility and anti-interference ability of the system.

Shock and vibration design:

- Reinforced structure: The reinforced shell and internal support structure are used to enhance the mechanical strength and effectively resist shock and vibration.

- Anti-vibration components: Anti-vibration gaskets, shock absorbers and other components are used to further improve the anti-vibration performance.

- Multi-layer PCB design: Through-hole technology is used to achieve electrical connection between different layers to enhance the overall strength of the PCB.

Wide temperature operating range:

- Supports an operating temperature range of -55°C to +125°C, adapting to various harsh environmental conditions.

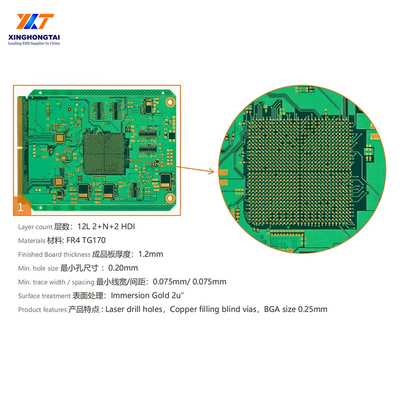

High-precision manufacturing process:

- Micro-circuit manufacturing: supports high-density wiring to ensure signal integrity and low noise.

- Surface mount technology (SMT): uses a fully automatic SMT production line to ensure high precision and consistency.

- Through-hole soldering (THT): combines through-hole soldering technology to provide a more secure electrical connection.

2.High-reliability components

Military-grade components:

- Use screened and certified military-grade components to ensure long-term stable operation in extreme environments.

Redundant design:

- Redundant design is used for key circuits to increase the reliability and fault tolerance of the system.

3.Advanced functional integration

High-performance processor:

- Supports high-performance processors such as NXP i.MX series, Intel Atom series, etc., providing excellent computing power and real-time processing capabilities.

Rich interface support:

- Network interface: supports high-speed network interfaces such as Gigabit Ethernet and fiber optic communication.

- Serial interface: supports multiple serial communication interfaces such as RS232/RS485 and CAN bus.

- Other interfaces: Supports general interfaces such as USB, SPI, I2C, UART, etc. to ensure compatibility with various peripherals.

AI acceleration function:

- Integrated neural processing unit (NPU), supports deep learning algorithms, suitable for AI application scenarios such as image recognition and voice processing.

- Provide optimized development tool chain and API to facilitate developers to carry out secondary development and customization.

4.Safety and protection

Electromagnetic shielding:

- Adopt metal shell and internal shielding design to provide good electromagnetic shielding effect and reduce electromagnetic interference.

Waterproof and dustproof:

- Support IP67 protection level, with waterproof and dustproof functions, suitable for outdoor and harsh environments.

Anti-salt spray corrosion:

- The surface is coated with anti-corrosion coating to ensure long-term stable operation in high humidity and salt spray environment.

Key attributes

Other attributes

Packaging and delivery

![]() ADVANCED MANUFACTURING CAPABILITIES

ADVANCED MANUFACTURING CAPABILITIES

| Process / Technology | Details |

| Fuji-Nxt – Multiple SMT Lines | Single and Double Sided Selective Wave |

| IPC 610 Class 2 & 3 Assembly | Quartz Crystal Processing |

| Clean & No-Clean Process | Thick / Thin Film Microelectronics |

| PBGA (PITCH BALL GRID ARRAY) | FBGA (FINE BALL GRADE ARRAY) to 0.5mm |

| High Melting Point Solder | Chip-on-Board / Wire Bond / Chip on chip |

| HMLV (High-Mix Low-Medium-Volume) PCB Assembly | Through Hole & SMT Mixed |

| Through Hole to SMT Conversion | Complete End Product Assembly |

| Avionics LRU Assembly | Leadless Chip |

| Overflow Assembly | Fine Pitch (0201 & 01005) |

| Box Build / Final Assembly / System Integration | Multi-Chip Modules |

| In-Circuit & Functional Testing | Conformal Coating - Automated and Manual |

| BGA Rework | Automated Cleaning Solutions |

| Hotplate Soldering | Potting |

| Track Cutting & Additive Pad Fixing | Flex Rigid PCB Assembly & Test |

| RF & Microwave – Assembly & Test | Hot Plate Soldering |

TEST CAPABILITIES

| In circuit Test – HP & Teradyne | BGA Rework Stations |

| Flying Probe Tester (Takaya) | Environmental Stress & Screening (ESS) – Active & Passive |

| 2D&3D Automatic XRAY Inspection | Functional Test Design, Development, Management |

| Automatic Optical Inspection | Diagnostic Test |

| Automatic Solder paste inspection | Firmware & System Test |

| Synod & DITMICO cable test | Calibration |

| Multiple JTAG test systems | NI & Key sight ATE |

| Boundary Scan | Reverse engineering |

| High Voltage & Insulation Testing |

CERTIFIED TEST &SCREENING FACILITY

| He / FC Bombing | Liquid Thermal Shock |

| Internal / External Visual Inspection | Thermal Humidity Bias Test |

| Fine & Gross Leak Testers | Burn in Chambers |

| Temperature Cycling (-65 to 200 deg C) | 3.5 Ton Vibration |

| Constant Acceleration | Thermal Vacuum Chamber |

![]()

![]()

![]()

![]()

![]()

Product Packaging:

The EMS PCB Assembly product will be packaged securely in anti-static bags and placed in a sturdy cardboard box with protective foam inserts.

Shipping:

We offer worldwide shipping for the EMS PCB Assembly product. Shipping options include standard, expedited, and express delivery. Customers can choose their preferred shipping method during the checkout process.

All shipments will be tracked and customers will receive a tracking number once the product has been shipped. Shipping fees will be calculated at checkout based on the destination and selected shipping method.

FAQ:

Q1: What service do you have?

XHT: We provide turnkey solutions including PCB design, Software development, PCB Assembly, Enclosure design, Mold-making, Plastic injection, Finish product assembly, and function testing.

Q2: What are the main products of your PCB/PCBA services?

XHT: Our PCB/PCBA services are mainly for industries including Industrial control, Home appliances main boards, automotive electronics, Consumer electronics, Medical equipment, bank equipment, smart home, etc.

Q3: Is XHT a factory or trade company?

XHT: XHT is a 20-year experienced professional contract manufacturer to provides a stop Turnkey PCB assembly and electronics manufacturing service.

Q4: Can we inspect quality during production?

XHT: Yes, we are open and transparent on each production process with nothing to hide. Customers are welcome to inspect our production process and check in-house.

Q5: How can we ensure our information should not let the third party see our design?

XHT: We are willing to sign an NDA effect by customer side local law and promise to keep customers' data in high confidential level.

Q6: What files are required to get a quotation from you?

XHT: For OEM PCBA projects, please provide the Gerber data/files and an indication of related technical requirements as well as any special requirements if you have them; For ODM projects, please provide a Function List, so our engineering team can work on it.

Q7: What is the standard delivery term?

XHT: Delivery terms of EXW, FCA, FOB, DDU, etc. are all available based on each quote.

Q8: How long does it take for a PCBA quote?

XHT: Depends on the project's complexity. Normally 1-2 weeks is enough for our engineers to evaluate.

Q9: Do you have any minimum order quantity (MOQ) requirements?

XHT: No, we do not have MOQ requirements, we can support your projects starting from prototypes to mass productions.

Tell us your requirements about the FAQ by CLICKING HERE, so that we can provide a solution to save your budget and meet your needs!