Professional Rogers Wireless Communication Surface Mount PCB Board Manufacturer

-

Highlight

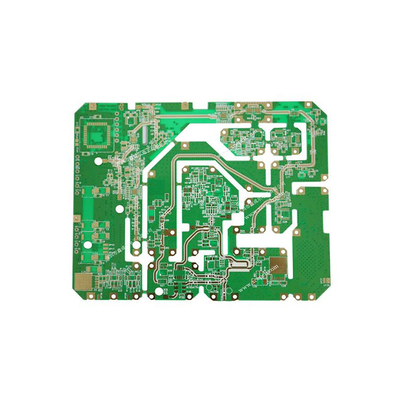

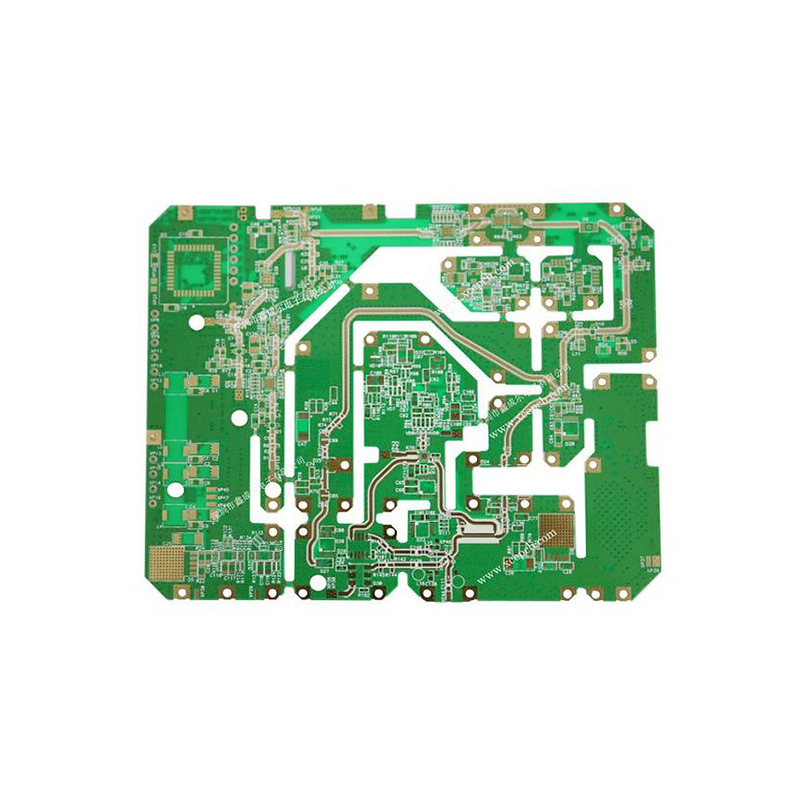

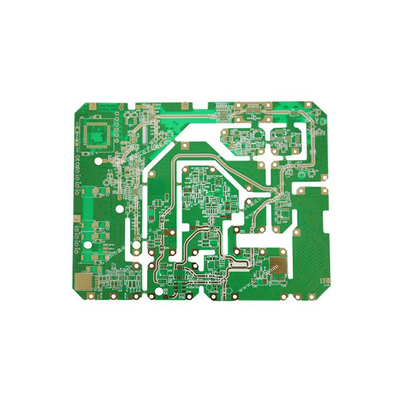

Rogers 4350 Surface Mount PCB

,Wireless Surface Mount PCB

,Professional Smt Board Assembly

-

Product NameProfessional Rogers Wireless Communication Surface Mount PCB Board Manufacturer

-

FeatureRogers 4350

-

Min. Line Width0.2mm, 3mi, 0.075mm, 0.075mm/0.075mm(3mil/3mil), 0.1 0mm

-

Min. Hole Size0.20mm, 0.1mm, 8 Mil, 0.254-0.40mm, 0.1mm-1mm

-

Min Trace/gap0.075mm Or 3mil

-

Copper Thickness1oz, 1/2OZ 1OZ 2OZ 3OZ, As Your Request, 0.5-3.0 Oz, 1 Oz

-

Base MaterialFR4, Aluminum, Rogers, CEM-1, TG

-

Place of OriginCHINA

-

Brand NameXHT

-

CertificationISO、IATF16949、RoSH、CE

-

Model NumberXHT PCB-11

-

Minimum Order QuantityNO MOQ

-

PriceUS$ 1-5/Pcs

-

Packaging DetailsCarton with foam bag

-

Delivery Time5-8 work days

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability600000+ PCS/mouth

Professional Rogers Wireless Communication Surface Mount PCB Board Manufacturer

Professional Rogers Wireless Communication Surface Mount PCB Board Manufacturer

What is Rogers PCB ?

Rogers PCB refers to printed circuit boards (PCBs) that are made using Rogers Corporation’s high-performance materials. Rogers Corporation is a global leader in advanced materials, and their PCB materials are known for their excellent electrical performance, thermal stability, and reliability. These materials are often used in high-frequency and high-speed applications, such as in the telecommunications, aerospace, and defense industries. Rogers PCBs are known for their low loss, high frequency, and high thermal conductivity properties, making them suitable for demanding electronic applications.

What are the materials for PCB ?

The materials used for PCBs (printed circuit boards) can vary depending on the specific requirements of the application. However, some common materials used in PCB manufacturing include:

FR-4: This is a widely used substrate material for PCBs. It is a type of glass-reinforced epoxy laminate that provides good electrical insulation and mechanical strength.

Copper: Copper is used as the conductive material in PCBs, forming the traces and pads that carry electrical signals.

Solder mask: This is a protective layer applied to the PCB to insulate the copper traces and prevent solder bridges during assembly.

Silkscreen: This layer is used for labeling components, test points, and other information on the PCB.

Substrate materials: In addition to FR-4, other substrate materials such as metal core, ceramic, and flexible materials like polyimide are used for specialized applications.

High-frequency materials: For high-speed and high-frequency applications, specialized materials with low dielectric constant and low loss tangent, such as Rogers materials, are used.

These materials are selected based on factors such as the operating environment, frequency of operation, thermal requirements, and mechanical constraints of the PCB.

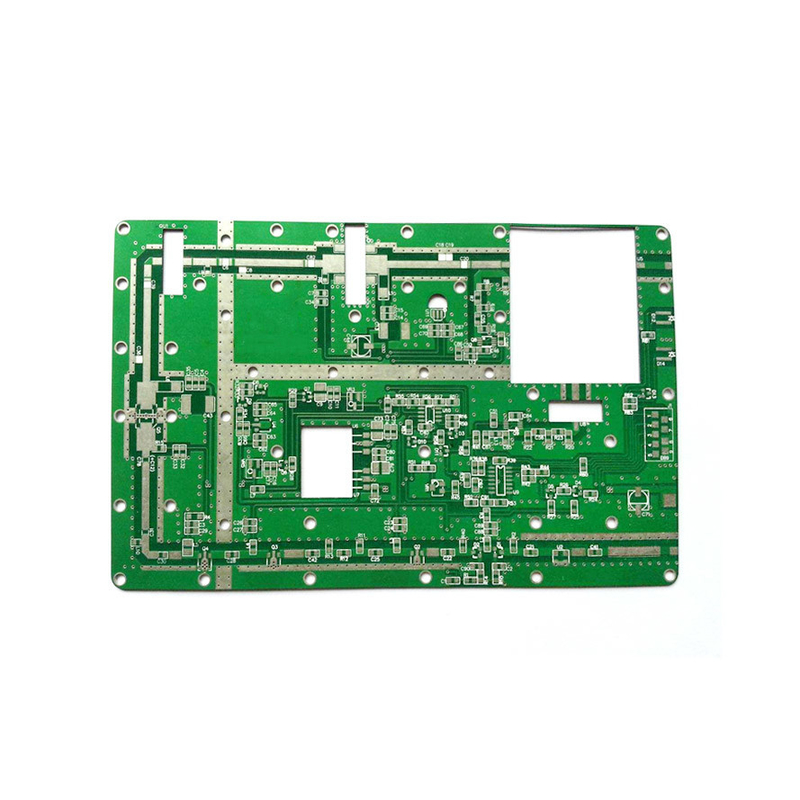

PCB Capacities and Technical Specification

| NO. | Items | Capabilities |

| 1 | Layers | 2-68L |

| 2 | Maximum machining size | 600mm*1200mm |

| 3 | Board thickness | 0.2mm-6.5mm |

| 4 | Copper thickness | 0.5oz-28oz |

| 5 | Min trace/space | 2.0mil/2.0mil |

| 6 | Minimum finished aperture | 0. 10mm |

| 7 | Maximum thickness to diameter ratio | 15:1 |

| 8 | Via treatment | Via, blind&buried via, via in pad, Copper in via … |

| 9 | Surface finish/treatment | HASL/HASL lead free, Chemical tin, Chemical Gold, Immersion gold Inmersion Silver/Gold, Osp, Gold Plating |

| 10 | Base Material | FR408 FR408HR, PCL-370HR;IT180A, Megtron 6(Panasonic);Rogers4350, Rogers4003, RO3003, Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| 11 | Solder mask color | Green.Black.Red.Yellow.White.Blue.Purple.Matte Green. Matte Black |

| 12 | Testing Service | AOI, X-Ray, Flying-Probe, Function Test, First Article Tester |

| 13 | Profiling Punching | Routing,V-CUT,Beveling |

| 14 | Bow&twist | ≤0.5% |

| 15 | HDI type | 1+n+1,2+n+2,3+n+3 |

| 16 | Min mechanical aperture | 0.1mm |

| 17 | Min laser aperture | 0.075mm |

Company introduction

XHT Technology Co.,Ltd was found in Huizhou , China.The company is strong and professional technical, with perfect quality assurance system and advances test-analyzed instrument. XHT is one of the Professional PCB manufacturer in China. We have professional PCB designer for your PCB layout requirement. We design single, double, and multi layers , Rigid, flexible, Flex-Rigid printed circuit boards, and PCB assembly.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

FAQ

| Q: What service do you have? XHT: We provide one-stop solutions including PCB manufacturing, SMT, component sourcing, final assembly, testing and other services. |

| Q: What is needed for PCB & PCBA quotation? XHT: For PCB: Gerber file and technic requirements(material,size, surface finish treatment, copper thickness,board thickness) and quantity you need. For PCBA: Files mentioned above, BOM, pick and place file. |

| Q: Are my files safe? XHT: Your files are held in complete safety and security.We protect the intellectual property for our customers in the whole process.. All documents from customers are never shared with any third parties. If requested by the client, we will sign an NDA subject to local laws on the client's side and promise to keep client data highly confidential. |

| Q: What are the main products of your PCB/PCBA services? XHT: Automotive, Military, Aerospace, Industry Control, Medical care, IOT, Smart Home, Robot, Auto parts, Camera, UAV. |

| Q: What is your minimum order quantity (MOQ)? XHT: Our MOQ is 1 PCS, we are able to handle Small as well as large volume production with flexibility. |