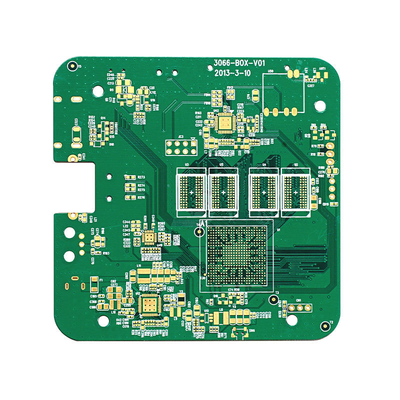

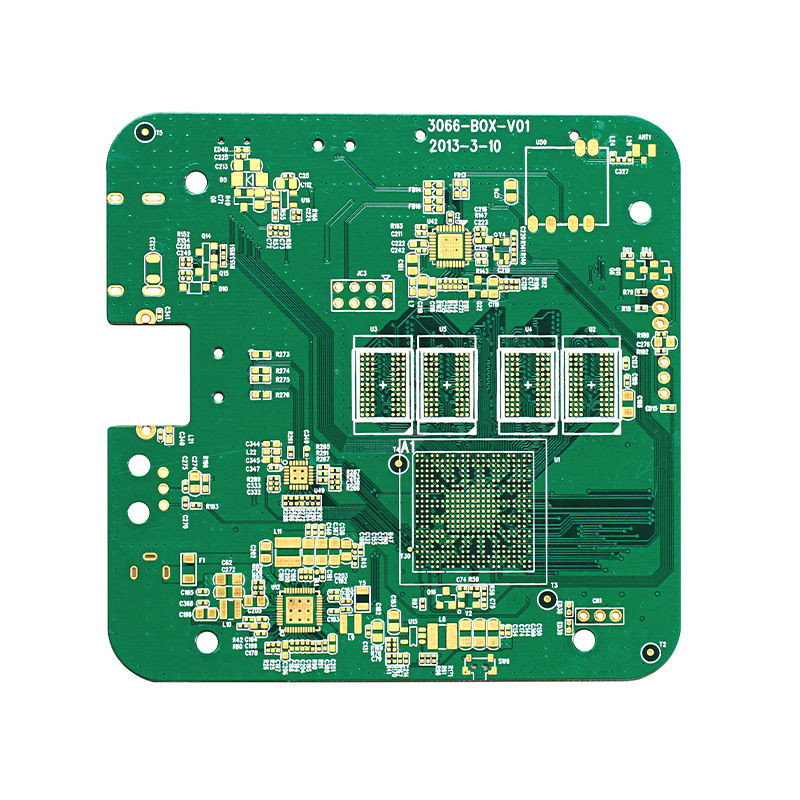

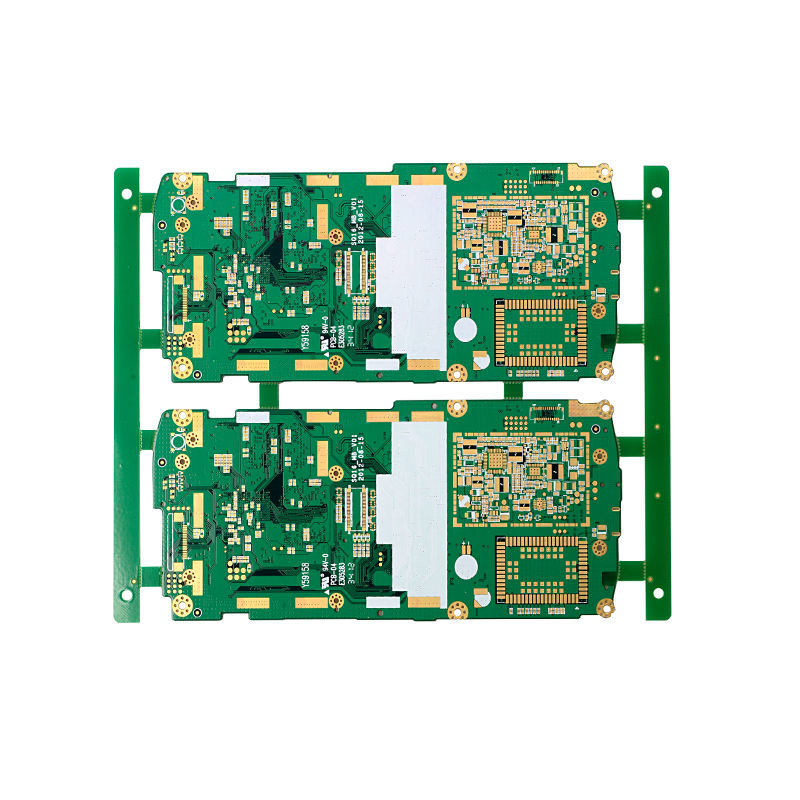

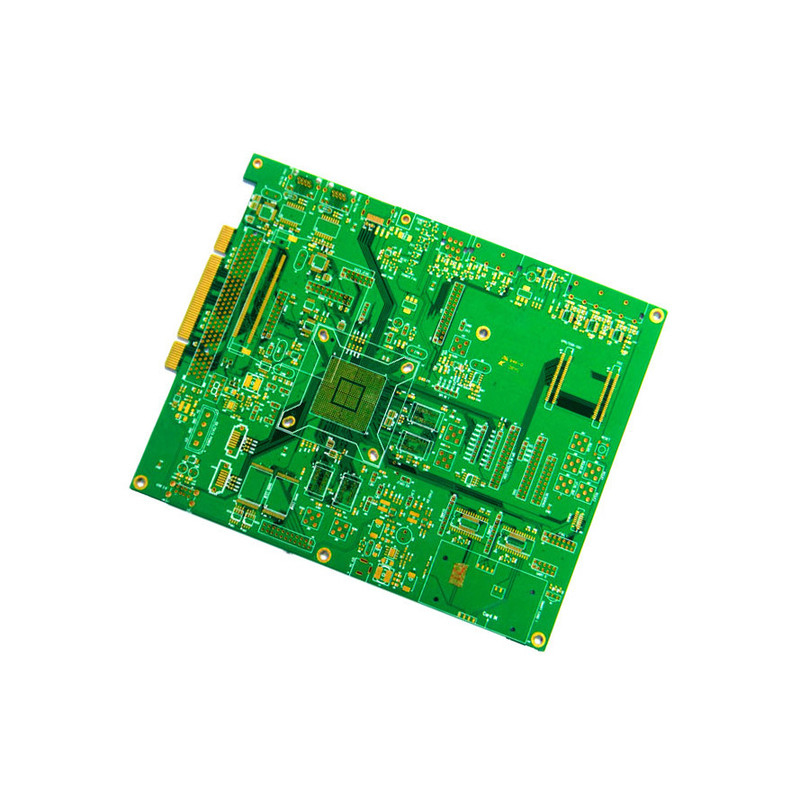

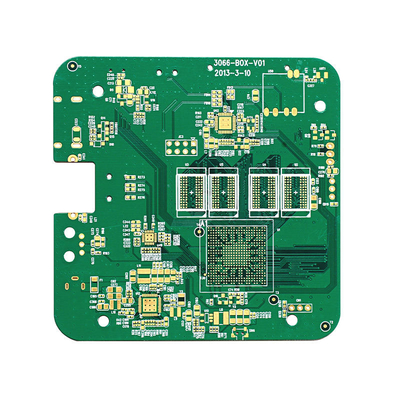

OEM Multilayer PCB Fabrication Electronic PCB Boards FR4 PCB Supplier One Stop Service

-

Highlight

IT180A Fr4 Circuit Board

,Turnkey Fr4 Circuit Board

,Customizable PCB Board Assembly

-

Product NameOEM Multilayer PCB Fabrication Electronic PCB Boards FR4 PCB Supplier One Stop Service

-

Copper Thickness1oz, 1/2OZ 1OZ 2OZ 3OZ, 2oz, 1oz(35um), 0.5-3.0 Oz

-

Base MaterialFR-4, Etc, Alu, High TG, FR-4/ceramic/cem-3/FR-1

-

Min. Line Spacing4mil, 0.003", 0.1mm4mil), 0.1mm, 4/4mil(0.1/0.1mm)

-

Min. Line Width4mil, 0.1mm, 0.1mm/4mi, 0.075mm/0.075mm(3mil/3mil), 3mi

-

Min. Hole Size0.2mm, 8 Mil, 0.10mm, 3mil (0.075mm), 0.004"

-

Surface FinishingHASL, OSP, HASL Lead Free, ENIG, Immersion Gold

-

ApplicationConsumer Electronics, Power, Automotive, Industry, Electronic Product

-

Place of OriginChina

-

Brand NameXHT

-

CertificationISO、IATF16949、RoSH

-

Model NumberXHT-FR-4 PCB Manufacturing-3

-

Minimum Order QuantityLow MOQ

-

PriceUS$ 1-5/Pcs

-

Packaging DetailsCarton with bubble bag

-

Delivery Time5-8 day

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability100000pcs/day

OEM Multilayer PCB Fabrication Electronic PCB Boards FR4 PCB Supplier One Stop Service

OEM Multilayer PCB Fabrication Electronic PCB Boards FR4 PCB Supplier One Stop Service

XHT Offering one stop service

* Rigid PCB;

* Flexible PCB;

* Rigid-flex PCB;

* HDI PCB;

* Gold-Plated PCB;

* High Frequency PCBs;

* Aluminum PCB;

* Copper Base Circuit Board;

* High TG PCB;

* Heavy Copper PCB;

* PCB Assembly;

* Components Sourcing;

* PCB / PCBA Testing.

PCB service Capacities and Technical Specification

| NO. | Items | Capabilities |

| 1 | Layers | 2-68L |

| 2 | Maximum machining size | 600mm*1200mm |

| 3 | Board thickness | 0.2mm-6.5mm |

| 4 | Copper thickness | 0.5oz-28oz |

| 5 | Min trace/space | 2.0mil/2.0mil |

| 6 | Minimum finished aperture | 0. 10mm |

| 7 | Maximum thickness to diameter ratio | 15:1 |

| 8 | Via treatment | Via, blind&buried via, via in pad, Copper in via … |

| 9 | Surface finish/treatment | HASL/HASL lead free, Chemical tin, Chemical Gold, Immersion gold Inmersion Silver/Gold, Osp, Gold Plating |

| 10 | Base Material | FR408 FR408HR, PCL-370HR;IT180A, Megtron 6(Panasonic);Rogers4350, Rogers4003, RO3003, Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| 11 | Solder mask color | Green.Black.Red.Yellow.White.Blue.Purple.Matte Green. Matte Black |

| 12 | Testing Service | AOI, X-Ray, Flying-Probe, Function Test, First Article Tester |

| 13 | Profiling Punching | Routing,V-CUT,Beveling |

| 14 | Bow&twist | ≤0.5% |

| 15 | HDI type | 1+n+1,2+n+2,3+n+3 |

| 16 | Min mechanical aperture | 0.1mm |

| 17 | Min laser aperture | 0.075mm |

PCBA Capabilities

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole, ISO SMT and DIP lines |

| Lead Time | Prototype : 15 work days. Mass order : 20~25 work days |

| Testing on products | Testing jig/mold , X-ray Inspection, AOI Test, Functional test |

| Quantity | Min quantity : 1pcs. Prototype, small order, mass order, all OK |

| Files needed | PCB : Gerber files(CAM, PCB, PCBDOC) Components : Bill of Materials(BOM list) Assembly : Pick-N-Place file |

| PCB Panel Size | Min size : 0.25*0.25 inches(6*6mm) Max size : 1200*600mm |

| Components details | Passive Down to 0201 size BGA and VFBGA Leadless Chip Carriers/CSP Double-sided SMT Assembly Fine Pitch to 0.8mils BGA Repair and Reball Part Removal and Replacement |

| Component package | Cut Tape, Tube, Reels, Loose Parts |

| PCB+ assembly process | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing |

Briefly Introduce Our Advantages

- Fast, high precision, complicated, high quality one-stop solution: ( PCB Prototype Service Manufacturing + Components Sourcing + PCB Prototype Service Assembly + Testing.)

- ISO9001,ISO14001, ISO13485, IATF16949 Certification.

- We support to give you better price and better on-time delivery.

- We offer 24*7 hours quotation service and engineering support.

- NDA is supported to protect your files safety.

Advanced PCB Manufacturing and PCB Assembly Equipment

XHT has imported the advanced machinery from US, Japan, German and Israel to improve our production and technical ability.We have set a great example the PCB prototype service field of flying probe testing,buried and blind via and special controlled impedance.We have a highly developed R&D division which has helped our factory successfully produce mechanical micro via,high density impedance and HDI.

![]()

![]()

![]()

![]()

![]()

![]()

FAQ

| Q: Which express companies do you cooperate with? XHT: We cooperate with express companies, including DHL, FedEX, UPS, TNT and EMS. And we also have our own freight forwarders, with lower shipping fees. |

| Q: What modes of transport are there? XHT: Usually includes express, air shipment, rail shipment and sea shipment. |

| Q: Popular field? XHT: Semiconductor, Smart Home, Medical Products, Smart Wearable, Industrial Control, IOT etc. |

| Q: Can you give us a preferential discount? XHT: Of course, we will offer a preferential discount for your large orders and confirm the order quickly. |

| Q: Why choose us? XHT: Professional and experienced R&D team. Advanced production equipment, scientific and reasonable process flow. Reliable and strict quality control system. We test all our products before shipment to make sure everything is in perfect condition. |

| Q: How long does it take for PCB quote? XHT: Normally 1 hours to 4hours as soon as receive internal engineer evaluate confirmation. |