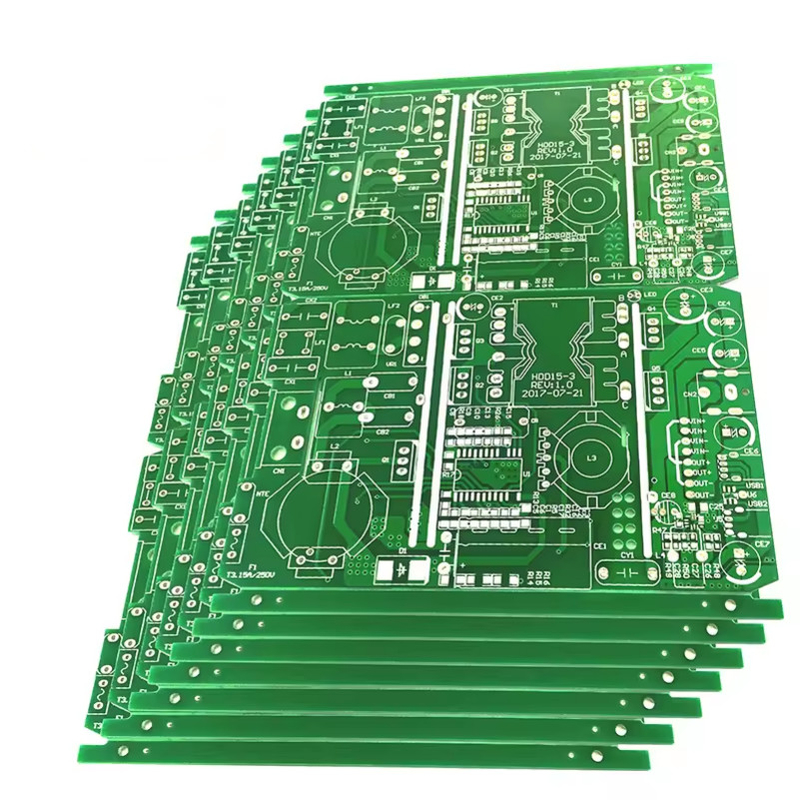

PCB Manufacturing Custom Pcba Prototype Service OEM ODM Pcb Printed Circuit Board Manufacturer In China

-

Highlight

Min Trace 2.0mil Prototype PCB Manufacturing

,Heavy Copper Prototype PCB Manufacturing

,Heavy Copper PCB Board Assembly

-

Product NamePCB Manufacturing Custom Pcba Prototype Service OEM ODM Pcb Printed Circuit Board Manufacturer In China

-

FeaturePCB Manufacture And Assembly

-

Maximum Machining Size600mm*1200mm

-

Profiling PunchingRouting/V-CUT/Beveling

-

High-end EquipmentFUJI NXT3/XPF Laminator

-

TestAOI/ X-Ray/Flying-Probe/Function Test

-

Other ServiceComponents Purchase /Assembly/Custom Packaging

-

Place of OriginChina

-

Brand NameXHT

-

CertificationISO、IATF16949、RoSH

-

Model NumberXHT-FR-4 PCB Manufacturing-9

-

Minimum Order QuantityLow MOQ

-

PriceUS$ 1-5/Pcs

-

Packaging DetailsCarton with bubble bag

-

Delivery Time5-8 day

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability100000pcs/day

PCB Manufacturing Custom Pcba Prototype Service OEM ODM Pcb Printed Circuit Board Manufacturer In China

PCB Manufacturing Custom Pcba Prototype Service OEM ODM Pcb Printed Circuit Board Manufacturer In China

PCB Wide Applications:

PCBs (Printed Circuit Boards) have wide applications across various industries and technologies. Some of the common applications of PCBs include:

Consumer Electronics: PCBs are extensively used in consumer electronics such as smartphones, tablets, laptops, televisions, and gaming consoles.

Automotive Industry: PCBs are used in automotive applications for engine control units, infotainment systems, safety systems, and various sensors.

Medical Devices: PCBs are crucial components in medical devices such as MRI machines, X-ray equipment, patient monitoring systems, and various diagnostic tools.

Aerospace and Defense: PCBs are used in avionics, radar systems, communication equipment, and various defense applications due to their reliability and performance in harsh environments.

Industrial Equipment: PCBs are used in industrial automation, control systems, robotics, and machinery for efficient and precise control of processes.

Telecommunications: PCBs are essential in telecommunications infrastructure, including base stations, routers, switches, and networking equipment.

Renewable Energy: PCBs are used in solar inverters, wind turbine control systems, and energy storage systems for efficient power conversion and control.

IoT (Internet of Things): PCBs are integral to IoT devices, enabling connectivity, data processing, and control in smart home devices, wearables, and industrial IoT applications.

LED Lighting: PCBs are used in LED lighting systems for efficient power distribution and control, enabling various lighting designs and functionalities.

Computer Hardware: PCBs are fundamental in computer hardware, including motherboards, graphics cards, and memory modules, enabling the functionality and performance of modern computing systems.

Overall, PCBs are essential in a wide range of applications, providing the foundation for electronic devices and systems across industries.

Some of the more common aerospace applications for PCB service include:

1. Monitoring equipment: Instrumentation, including accelerometers, pressure sensors, microphones, and torque and force sensors All use PCB assembly service as part of their basic functions. These products are used in the engines and cockpits of aircraft and rockets to monitor vehicle functions and communicate with ground control systems.

2. Test Equipment: In addition to its function as an aircraft, PCB assembly service are involved in the development and testing of aircraft. Test equipment that collects data during structural, vibration, and flight testing uses a PCB as its core. This data can be used to develop more efficient, efficient and safer aircraft.

The following are the common types of PCB substrates:

- FR-4: Glass fiber + epoxy resin. It is the most commonly used PCB material, but the Tg is only about 130. If the subsequent processing environment of the product or the operating environment temperature is high, High Tg FR-4 is recommended.

- High Tg FR-4: Glass fiber + epoxy resin, the use is second only to FR-4. Tg above 150°C is High Tg.

- CEM-1: The center is tissue paper, and the surface is covered with glass cloth + epoxy resin.

- CEM-3: The center is glass non-woven cloth, and the surface is covered with glass cloth + epoxy resin.

- Ceramic substrate (Ceramic PCB): ceramic powder + glass fiber.

- Teflon PCB (Teflon PCB): Teflon + glass fiber.

We are PCB Fabrication & PCB Assembly Reliable Supplier in China

Introduction

We have a strong electronic component supply chain, we can offer competitive price for your BOM list.

Service

We specialize in providing comprehensive EMS solutions to meet the unique needs of our clients.

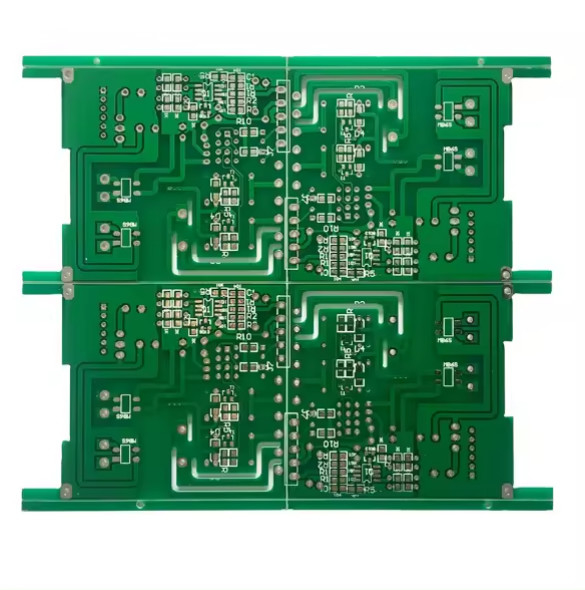

Our PCB Fabrication Capability& Technical Specification

| NO. | Items | Capabilities |

| 1 | Layers | 2-68L |

| 2 | Maximum machining size | 600mm*1200mm |

| 3 | Board thickness | 0.2mm-6.5mm |

| 4 | Copper thickness | 0.5oz-28oz |

| 5 | Min trace/space | 2.0mil/2.0mil |

| 6 | Minimum finished aperture | 0. 10mm |

| 7 | Maximum thickness to diameter ratio | 15:1 |

| 8 | Via treatment | Via, blind&buried via, via in pad, Copper in via … |

| 9 | Surface finish/treatment | HASL/HASL lead free, Chemical tin, Chemical Gold, Immersion gold Inmersion Silver/Gold, Osp, Gold Plating |

| 10 | Base Material | FR408 FR408HR, PCL-370HR;IT180A, Megtron 6(Panasonic);Rogers4350, Rogers4003, RO3003, Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| 11 | Solder mask color | Green.Black.Red.Yellow.White.Blue.Purple.Matte Green. Matte Black |

| 12 | Testing Service | AOI, X-Ray, Flying-Probe, Function Test, First Article Tester |

| 13 | Profiling Punching | Routing,V-CUT,Beveling |

| 14 | Bow&twist | ≤0.5% |

| 15 | HDI type | 1+n+1,2+n+2,3+n+3 |

| 16 | Min mechanical aperture | 0.1mm |

| 17 | Min laser aperture | 0.075mm |

![]()

![]()

![]()

![]()

![]()

![]()

FAQ

| Q: Are you factory? XHT: Our factory is located in Building 6, Fuyuan industrial park, Qiaotang road, Fuyong street , Shenzhen city, China |

| Q: How about the shipping cost? XHT: The Shipping cost depends on the destination, the weight and volume of the goods as well as the quotation of DHL/FEDEX/ freight forwarder at that time. You can inform us of the transportation way you need before placing an order. |

| Q: How can we guarantee quality? XHT: Always a pre-production sample before mass production; Always final Inspection and test report before shipment; |

| Q: Why should we buy from XHT? XHT: Professional and experienced R&D team. Advanced production equipment, scientific and reasonable process flow. Reliable and strict quality control system. We test all our products before shipment to make sure everything is in perfect condition. From the design to the complete product, XHT's professional team will put you at ease |