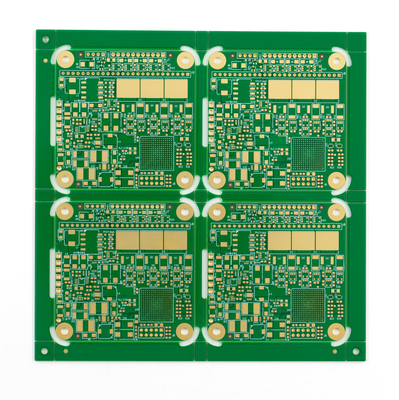

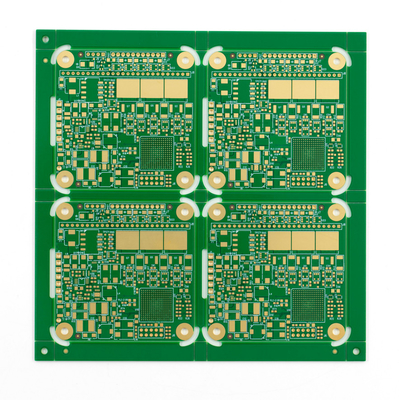

Turnkey Service FR4 PCB Printed Circuit Board Factory & PCB Fabrication Manufacturer

-

Highlight

IATF16949 Prototype PCB Manufacturing

,Electronic Prototype PCB Manufacturing

,Lead Free Metal Core Board

-

Product NameTurnkey Service FR4 PCB Printed Circuit Board Factory & PCB Fabrication Manufacturer

-

FeaturePCB Manufacture And Assembly

-

Maximum Machining Size600mm*1200mm

-

Profiling PunchingRouting/V-CUT/Beveling

-

High-end EquipmentFUJI NXT3/XPF Laminator

-

TestAOI/ X-Ray/Flying-Probe/Function Test

-

Other ServiceComponents Purchase /Assembly/Custom Packaging

-

Place of OriginChina

-

Brand NameXHT

-

CertificationISO、IATF16949、RoSH

-

Model NumberXHT-FR-4 PCB Manufacturing-9

-

Minimum Order QuantityLow MOQ

-

PriceUS$ 1-5/Pcs

-

Packaging DetailsCarton with bubble bag

-

Delivery Time5-8 day

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability100000pcs/day

Turnkey Service FR4 PCB Printed Circuit Board Factory & PCB Fabrication Manufacturer

Turnkey Service FR4 PCB Printed Circuit Board Factory & PCB Fabrication Manufacturer

What is FR4 PCB ?

FR4 PCB refers to a type of printed circuit board (PCB) material that is made from a flame-retardant epoxy resin. The “FR” stands for flame retardant, and the “4” indicates the grade of the material according to the NEMA LI-1-1998 standard. FR4 PCBs are widely used in electronic devices and are known for their high strength, durability, and resistance to heat and moisture. They are commonly used in applications such as consumer electronics, telecommunications equipment, and industrial machinery.

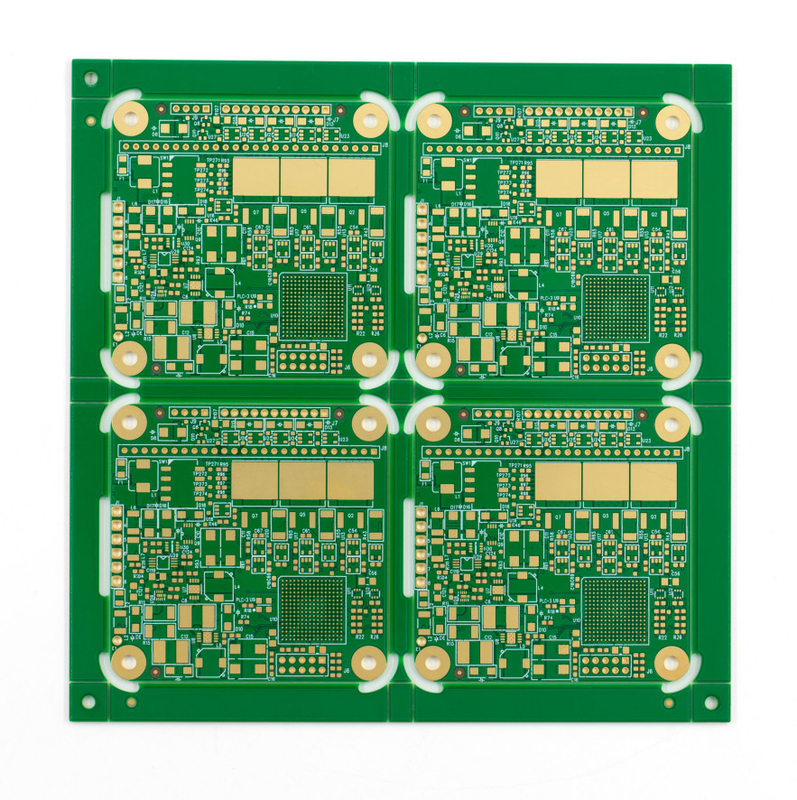

Turnkey Service of PCB Manufacturing

Turnkey service of PCB manufacturing refers to a comprehensive service provided by a PCB manufacturer that covers the entire process of PCB production, from design and prototyping to fabrication and assembly. This means that the manufacturer takes care of all aspects of the PCB manufacturing process, including sourcing components, PCB fabrication, assembly, testing, and quality control.

With turnkey PCB manufacturing, the customer can simply provide the design specifications and requirements, and the manufacturer will handle the rest, ensuring that the finished PCBs meet the customer’s specifications and quality standards. This approach can save time and resources for the customer, as they do not have to manage multiple suppliers or coordinate different stages of the manufacturing process.

XHT is a PCB Fabrication & PCB Assembly Professional Manufacturer

Introduction

We have a strong electronic component supply chain, we can offer competitive price for your BOM list.

Service

We specialize in providing comprehensive EMS solutions to meet the unique needs of our clients.

Our PCB Fabrication Capablity & Technical Specification

| NO. | Items | Capabilities |

| 1 | Layers | 2-68L |

| 2 | Maximum machining size | 600mm*1200mm |

| 3 | Board thickness | 0.2mm-6.5mm |

| 4 | Copper thickness | 0.5oz-28oz |

| 5 | Min trace/space | 2.0mil/2.0mil |

| 6 | Minimum finished aperture | 0. 10mm |

| 7 | Maximum thickness to diameter ratio | 15:1 |

| 8 | Via treatment | Via, blind&buried via, via in pad, Copper in via … |

| 9 | Surface finish/treatment | HASL/HASL lead free, Chemical tin, Chemical Gold, Immersion gold Inmersion Silver/Gold, Osp, Gold Plating |

| 10 | Base Material | FR408 FR408HR, PCL-370HR;IT180A, Megtron 6(Panasonic);Rogers4350, Rogers4003, RO3003, Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| 11 | Solder mask color | Green.Black.Red.Yellow.White.Blue.Purple.Matte Green. Matte Black |

| 12 | Testing Service | AOI, X-Ray, Flying-Probe, Function Test, First Article Tester |

| 13 | Profiling Punching | Routing,V-CUT,Beveling |

| 14 | Bow&twist | ≤0.5% |

| 15 | HDI type | 1+n+1,2+n+2,3+n+3 |

| 16 | Min mechanical aperture | 0.1mm |

| 17 | Min laser aperture | 0.075mm |

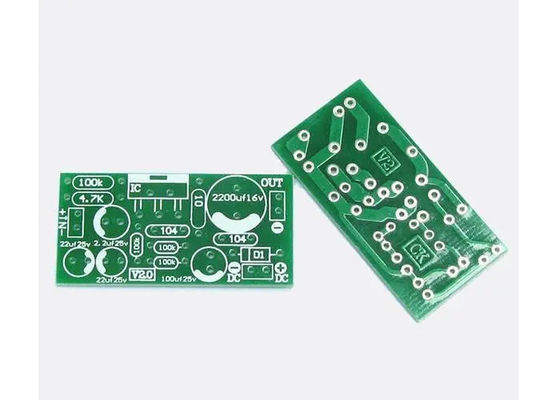

Our PCB Assembly Advantages

- Professional Surface-mounting and Through-hole soldering Technology

- Various sizes like 1206, 0805, 0603 components SMT technology

- ICT(In Circuit Test), FCT(Functional Circuit Test) technology.

- Main PCBA With CE, FCC, Rohs Approval

- Nitrogen gas reflow soldering technology for SMT.

- High Standard SMT& Solder Assembly Line

- High density interconnected board placement technology capacity.

PCBA production Lines

Our company currently has 12 high-speed SMT lines with a monthly production capacity of 600 million points. 7 wave soldering production lines and 10 post-DIP soldering lines. We can make special fixtures according to customer requirements and product conditions to ensure product reliability and effectively improve plug-in efficiency. Our DIP post-welding personnel have rich experience, and have formulated detailed standardized operation guidelines and SOP operation instructions to meet the high-quality requirements of high-end customers.

Company Profile

XHT focuses on One-stop Service including: PCB Fabrication, Electronic Components Sourcing, Main PCBA, Function Test, Product Assembly. XHT has manufacturing Main PCBA for over 20 years. During this time technology has moved forward at an amazing pace. By keeping abreast of technology, we can populate any Main PCBA with SMD and conventional Components, single or double sided, one layer, to multilayer to any of your requirements and configurations.

![]()

![]()

![]()

![]()

![]()

![]()

FAQ

| Q: How can we guarantee quality? XHT: Always a pre-production sample before mass production; Always final Inspection and test report before shipment; |

| Q: Why should we buy from XHT? XHT: Professional and experienced R&D team. Advanced production equipment, scientific and reasonable process flow. Reliable and strict quality control system. We test all our products before shipment to make sure everything is in perfect condition. From the design to the complete product, XHT's professional team will put you at ease |

| Q: IS PRODUCT PICTURES AND LABELS AVAILABLE? XHT: We will offer after you place an order or before shipment. |

| Q: WHAT IS YOUR TERMS OF PACKING? XHT: Generally, we pack our goods in neutral white boxes and brown cartons. |