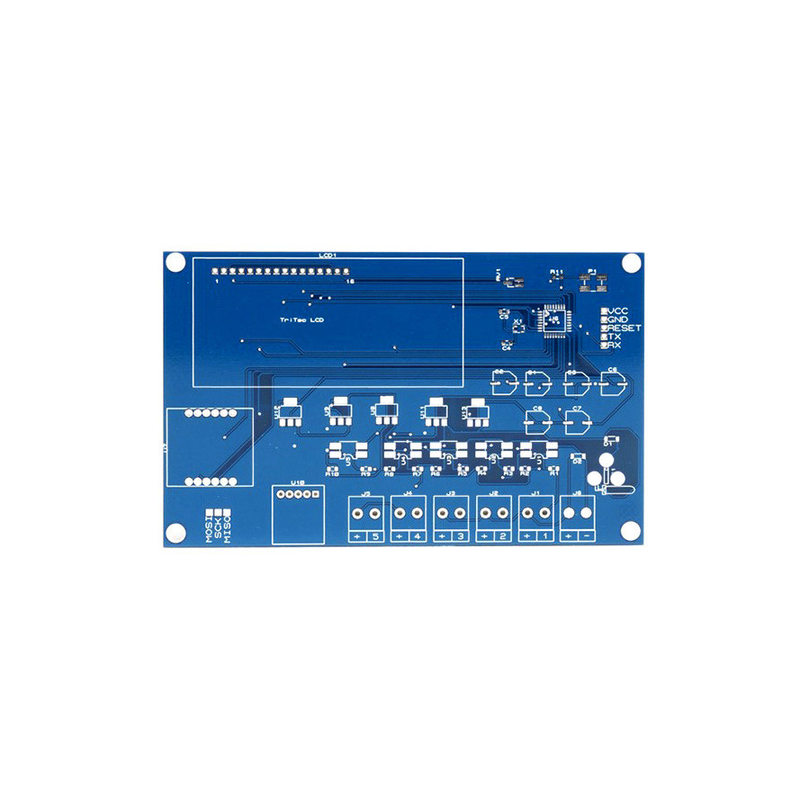

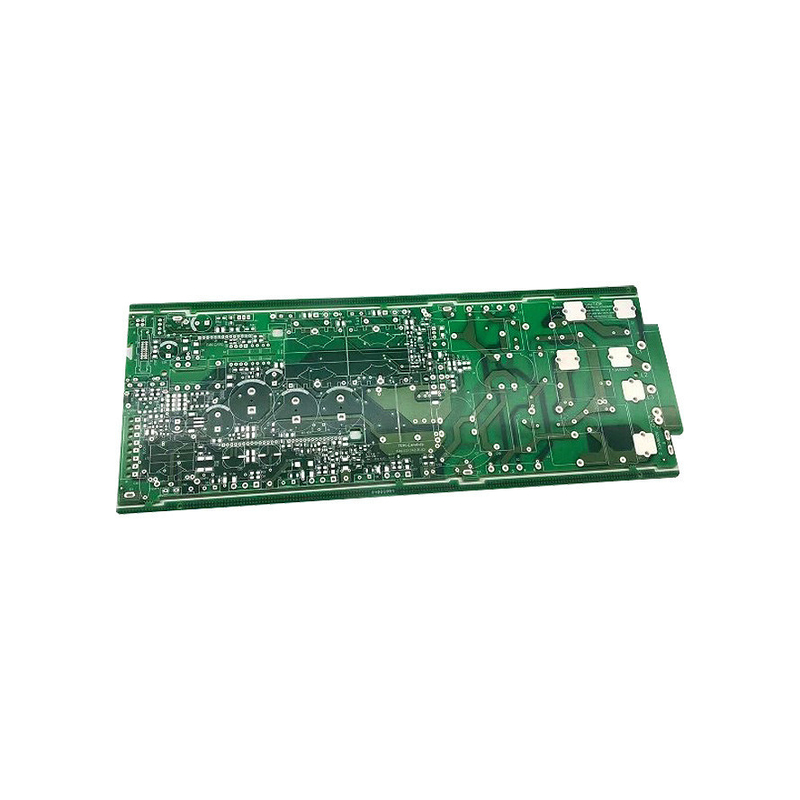

Printed Circuit Board Manufacturing Professional PCB Fabrication One Stop Service

-

Highlight

Professional Circuit Board Manufacturing

,Industrial Circuit Board Manufacturing

,One Stop Service Prototype PCB Assembly

-

Thickness0.2mm-6.0mm

-

Base MaterialFR-4,CEM-1,CEM-3,Polyimild,PTFE/Rogers

-

Maximum Machining Size600mm*1200mm

-

Board Thickness0.2-6.0mm

-

Dielectric Strength≥40KV/mm

-

Min. Line Width/Spacing0.1mm/0.1mm

-

Min. Panel Size10mm*10mm

-

Profiling PunchingRouting/V-CUT/Beveling

-

ManufacturingFR-4 PCB Manufacturing

-

Rohs CompliantYes

-

Board Size78x102mm

-

FeaturePCB Manufacture And Assembly

-

UsageOEM Electronics

-

Place of OriginChina

-

Brand NameXHT

-

CertificationISO、IATF16949、RoSH

-

Model NumberXHT-FR-4 PCB Manufacturing-5

-

Minimum Order QuantityLow MOQ

-

PriceUS$ 1-5/Pcs

-

Packaging DetailsCarton with bubble bag

-

Delivery Time5-8 day

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability100000pcs/day

Printed Circuit Board Manufacturing Professional PCB Fabrication One Stop Service

Printed Circuit Board Manufacturing Professional PCB Fabrication One Stop Service

Great Services

As IATF16949 verified circuit board factory, will provide DFM Analysis for your every order, as well as low volume and medium volume production runs. We verify all details of your files, including Gerber files, to allow you to correct your PCB design before manufacturing, saving significant time and cost. We use ERP and MES system, which can protect all your project files and also control all the parts quality from the beginning to the end. As a PCB prototype supplier, we have complete and mature tracking system by the two systems, which can solve the problems quickly, also guarantees on time delivery of quick turn printed circuit board.

Advantages of CESGATE PCB Prototype Service

Test each function of the product according to the test case, and provide the test report. We can provide services such as electrical measurement and aging according to customer needs to improve product reliability. For each process, CESGATE has formulated perfect operation instructions, and customized targeted inspection standards according to products in different industries, so as to improve the pass-through rate of products from each link.

PCB Prototype Service Capacities and Technical Specification

| NO. | Items | Capabilities |

| 1 | Layers | 2-68L |

| 2 | Maximum machining size | 600mm*1200mm |

| 3 | Board thickness | 0.2mm-6.5mm |

| 4 | Copper thickness | 0.5oz-28oz |

| 5 | Min trace/space | 2.0mil/2.0mil |

| 6 | Minimum finished aperture | 0. 10mm |

| 7 | Maximum thickness to diameter ratio | 15:1 |

| 8 | Via treatment | Via, blind&buried via, via in pad, Copper in via … |

| 9 | Surface finish/treatment | HASL/HASL lead free, Chemical tin, Chemical Gold, Immersion gold Inmersion Silver/Gold, Osp, Gold Plating |

| 10 | Base Material | FR408 FR408HR, PCL-370HR;IT180A, Megtron 6(Panasonic);Rogers4350, Rogers4003, RO3003, Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| 11 | Solder mask color | Green.Black.Red.Yellow.White.Blue.Purple.Matte Green. Matte Black |

| 12 | Testing Service | AOI, X-Ray, Flying-Probe, Function Test, First Article Tester |

| 13 | Profiling Punching | Routing,V-CUT,Beveling |

| 14 | Bow&twist | ≤0.5% |

| 15 | HDI type | 1+n+1,2+n+2,3+n+3 |

| 16 | Min mechanical aperture | 0.1mm |

| 17 | Min laser aperture | 0.075mm |

XHT Company Descripiton

Introduction

We have a strong electronic component supply chain, we can offer competitive price for your BOM list.

Service

We specialize in providing comprehensive EMS solutions to meet the unique needs of our clients.

![]()

![]()

![]()

![]()

![]()

FAQ

| Q: Are my files safe? XHT: Your files are kept very safe, and we are protecting intellectual property for our clients throughout the process. All files provided by customers are never shared with any third party. |

| Q: MOQ? XHT: There is no MOQ in POE. We are able to flexibly handle small and large batches. |

| Q: Do you have any other services? XHT: We mainly focus on the procurement services of PCB + assembly + components. In addition, we can also provide programming, testing, cable, housing assembly services. |

| Q: What is your inspection policy? How do you control the quality? XHT: In order to ensure the quality of PCB products, flying probe inspection is usually used; electrical fixtures, automatic optical inspection (AOI), BGA parts x-ray inspection, first article inspection ( FAI) etc. |